Nhanganyaya

Sezvo muviri wemotokari uri mutakuri wezvimwe zvikamu zvemotokari, tekinoroji yayo yekugadzira inotaridza zvakananga huwandu hwese hwekugadzira hwemotokari.Welding inzira yakakosha yekugadzira mukati mekugadzira mota muviri.Parizvino, matekinoroji emagetsi anoshandiswa kugadzira mota muviri welding anonyanya kusanganisira resistance spot welding, MIG welding, MAG welding uye laser welding.

Laser welding tekinoroji seyepamusoro optoelectromechanical yekubatanidza welding tekinoroji, kana ichienzaniswa neyechinyakare mota yemuviri welding tekinoroji, ine zvakanakira zvesimba repamusoro density, kukurumidza welding kumhanya, kudiki welding kusagadzikana uye deformation, uye yakanaka kuchinjika.

Chimiro chemuviri wemotokari chakaoma, uye zvikamu zvaro zvakanyanya kutetepa-madziro uye akakombama.Mota yemoto welding inotarisana nezvimwe zvinonetsa, sekuchinja kwezvinhu zvemuviri, ukobvu hwakasiyana hwenhengo dzemuviri, diversified welding trajectory uye majoini mafomu.Uye zvakare, mota welding yemuviri ine zvakakwirira zvinodikanwa pane welding mhando uye welding kunyatsoita.

Zvichienderana neakakodzera welding process paramita, laser welding inogona kuve nechokwadi chekuneta kwesimba uye kukanganisa kuoma kwezvinhu zvakakosha zvemuviri wemotokari, kuitira kuti ive nechokwadi chemhando yewelding uye hupenyu hwebasa remuviri wemotokari.Laser welding tekinoroji inogona kuchinjika kune akasiyana majoini mafomu, ukobvu hwakasiyana uye akasiyana emhando emhando dzeauto nhengo dzemuviri welding, kusangana nezvinodiwa zvinoshanduka zvekugadzira auto body.Naizvozvo, laser welding tekinoroji yakakosha tekinoroji nzira yekuwana yakakwirira-mhando yekusimudzira indasitiri yemotokari.

Laser welding tekinoroji yemuviri wemotokari

Laser yakadzika yekupinda welding tekinoroji yemuviri wemotokari

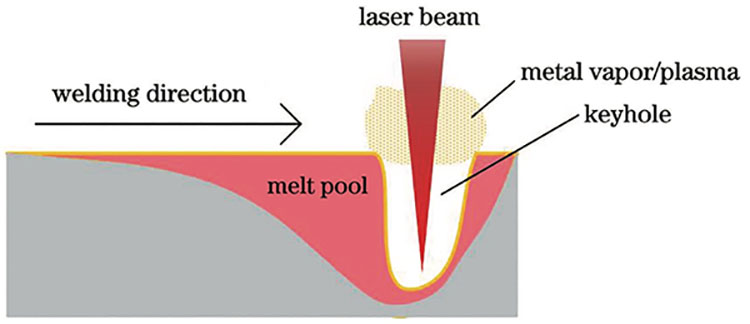

Nheyo yelaser yakadzika yekupinda welding process (Mufananidzo 1) ndeiyi: kana iyo laser simba density inosvika pane imwe nhanho, pamusoro pechinhu chinoputika, ichigadzira kiyi hole.Kana iyo simbi mhute yekumanikidza mugomba inosvika pachiyero chine simba neiyo static pressure uye kusimba kwepasi kwemvura yakatenderedza, laser inogona kuvhenekerwa kusvika pasi pegomba kuburikidza nekiyi, uye nekufamba kwelaser beam, inoenderera. weld inogadzirwa.Munguva ye laser yakadzika yekupinda welding process, hapana chikonzero chekuwedzera yekubatsira flux kana yekuzadza, uye iyo workpiece yega zvinhu zvinogona kubatanidzwa pamwechete.

FIG.1 Schematic diagiramu ye laser yakadzika yekupinda welding process

Iyo weld inowanikwa nelaser yakadzika yekupinda welding inowanzo yakatsetseka uye yakatwasuka, uye iyo deformation idiki, iyo inobatsira kuvandudza iko kwekugadzira kwemuviri wemotokari.Iyo yakakwira tensile simba re weld inovimbisa welding mhando yemuviri wemotokari.Iyo welding yekumhanyisa inokurumidza, iyo inobatsira kuvandudza kugona kwekugadzira welding.

Mukuita kwemotokari yemoto welding, kushandiswa kwe laser yakadzika yekupinda welding process kunogona kuderedza zvakanyanya huwandu hwezvikamu, molds uye welding maturusi, nekudaro kuderedza huremu hwemuviri uye mutengo wekugadzira.Nekudaro, iyo laser yakadzika yekupinda welding process ine kushivirira kwakashata kune gaka regungano rezvikamu zvakasungwa, uye gaka regungano rinoda kudzorwa pakati pe0.05 ne2 mm.Kana gaka regungano rakakurisa, zvirema zvewelding senge pores zvichaitika.

Tsvagiridzo yazvino inoratidza kuti iyo weld ine yakanaka kuumbwa kwepasi, kushoma kwemukati kukanganisa uye yakanakisa mechaniki zvivakwa zvinogona kuwanikwa nekukwenenzvera maparamita e laser yakadzika yekupinda welding muwelding yezvinhu zvakafanana zvemuviri wemotokari.Iyo yakanakisa mechanic properties ye weld inogona kusangana nezvinodiwa zvewelding zvikamu zvemuviri wemotokari.Nekudaro, mumotokari muviri welding, iyo dissimilar simbi laser yakadzika yekupinda welding tekinoroji inomiririrwa nealuminium alloy uye simbi haina kukura.Kunyangwe masonwe emagetsi ane mashandiro akanakisa anogona kuwanikwa nekuwedzera shanduko yekuchinja, maitiro epesvedzero yeakasiyana ekuchinja layer zvinhu paIMC layer uye maitiro avo ekuita pane weld microstructure haana kujeka, uye kumwe kutsvagisa kunodiwa.

Mota yemuviri laser waya yekuzadza welding maitiro

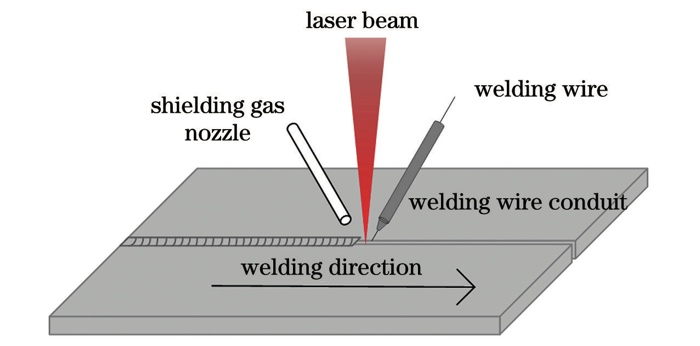

Nheyo yelaser filler wire welding process ndeiyi inotevera: iyo welded joint inoumbwa nekutanga kuzadza iyo chaiyo welding waya muweld kana kudyisa waya welding panguva imwe chete panguva yelaser welding process.Izvi zvakaenzana nekuisa inenge homogeneous welding waya zvinhu mu weld pool panguva ye laser deep penetration welding.Iyo schematic dhizaini yeiyo laser filler waya welding process inoratidzwa muMufananidzo 2.

FIG.2 Schematic dhizaini yelaser waya yekuzadza welding process

Kuenzaniswa nelaser yakadzika yekupinda welding, laser waya yekuzadza welding ine mabhenefiti maviri mu auto body welding: chekutanga, inogona kuvandudza zvakanyanya kushivirira kwegeji regungano pakati pezvikamu zvemuviri zvemotokari kuti zvisungirwe, uye kugadzirisa dambudziko iro laser yakadzika yekupinda welding. inoda kuwanda kwegorofu clearance;Chechipiri, kugoverwa kwetishu yenzvimbo ye weld inogona kuvandudzwa nekushandisa welding waya dzine akasiyana maumbirwo emukati, uye ipapo weld performance inogona kudzorwa.

Mukuita kwekugadzira mota yemuviri, iyo laser waya yekuzadza welding process inonyanya kushandiswa kugadzira welding aluminium alloy uye simbi nhengo dzemuviri.Kunyanya mukugadzirisa kwealuminium alloy zvikamu zvemuviri wemotokari, kushushikana kwepasi kwedziva rakanyungudutswa kudiki, zviri nyore kutungamira mukudonha kwedziva rakanyungudutswa, uye iyo laser waya yekuzadza welding process inogona kugadzirisa zvirinani dambudziko rekupunzika kwedziva. nekunyungudusa waya wewelding.

Laser brazing tekinoroji yemuviri wemotokari

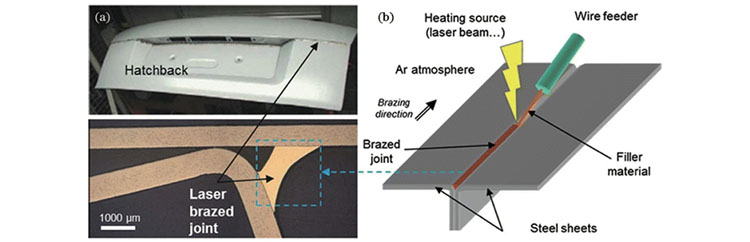

Nheyo yelaser brazing process ndeiyi inotevera: iyo laser inoshandiswa senge sosi yekupisa, iyo laser beam inovhenekerwa pamusoro peiyo welding waya mushure mekutariswa, waya welding inonyungudutswa, waya yakanyunguduka inodonha uye inozadzwa pakati. zvikamu kuti welded, uye metallurgical migumisiro akadai kunyunguduka uye diffusion kuitika pakati filler simbi uye workpiece, kuitira kuti workpiece kwakabatana.Kusiyana nelaser waya yekuzadza welding process, iyo laser brazing process inongonyungudutsa waya uye hainyungudutsa workpiece kuti isungirwe.Laser brazing ine yakanaka welding kugadzikana, asi kusimba kwekusimba kweweld kwakaderera.FIG.3 inoratidza kushandiswa kwelaser brazing process mumotokari boot lid welding.

FIG.3 Kushandiswa kwelaser brazing mumotokari: (a) laser welding yekumashure hood;(b) Schematic diagram ye laser brazing

Mukuita kwemoto welding yemotokari, laser brazing process inonyanya kubatanidza nhengo dzemuviri dzine yakaderera majoini zvinodikanwa, senge welding pakati pechivharo chepamusoro uye pamadziro emadziro emuviri, welding pakati pepamusoro nepasi pezvitunha. chivharo, nezvimwewo, Volkswagen, Audi uye mamwe emhando yepamusoro-yepamusoro pevhavha ari kushandisa laser brazing process.

Izvo zvakanyanya kukanganisa mu laser brazing welding seam yemotokari muviri zvinosanganisira kumucheto kuruma, porosity, weld deformation, etc. Kukanganisa kunogona kudzvinyirirwa pachena nekugadzirisa maitiro ekugadzirisa uye kushandisa multi-focus laser brazing process.

Laser arc composite welding tekinoroji yemuviri wemotokari

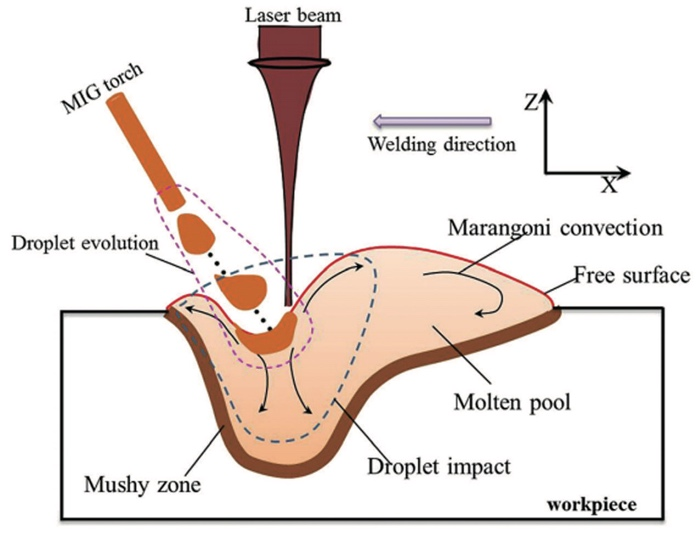

Nheyo yelaser-arc composite welding process ndeiyi inotevera: kushandisa maviri kupisa masosi e laser uye arc kuita pamusoro peiyo workpiece kuti isungirwe panguva imwe chete, iyo workpiece inonyungudutswa uye yakasimbiswa kuita weld.Mufananidzo 4 unoratidza dhizaini yelaser-arc composite welding process.

FIG.4 Schematic diagiramu ye laser-arc composite welding process

Laser-arc composite welding ine zvakanakira ese ari maviri laser welding uye arc welding: chekutanga, pasi pekuita kweviri kupisa masosi, kumhanya kwewelding kunovandudzwa, kupisa kwekuisa kudiki, iyo weld deformation idiki, uye hunhu hwelaser welding. zvinochengetwa;Chechipiri, ine bhiriji kugona kurinani uye kushivirira kukuru kwegap regungano;Chechitatu, kuwanda kwekusimba kwedziva rakanyungudutswa kunononoka, izvo zvinoita kuti ubvise hurema hwewelding senge pores uye makatsemuka, uye kuvandudza chimiro uye kushanda kwenzvimbo inobatwa nekupisa.Chechina, nekuda kwekuita kwearc, inogona weld zvinhu zvine high reflectivity uye high thermal conductivity, uye huwandu hwezvinhu zvekushandisa hwakakura.

Mukuita kwekugadzira mutumbi wemotokari, iyo laser-arc composite welding process inonyanya kupinza aluminium alloy zvikamu zvemuviri uye aruminiyamu-simbi simbi dzakasiyana, uye welding inoitwa kune zvikamu zvine maburi mahombe egungano, senge kukwenenzverwa kwezvikamu zve. gonhi remotokari, nekuti gaka regungano rinobatsira pakutamba kwebhiriji kuita kwelaser-arc composite welding.Uye zvakare, laser-MIG arc composite welding tekinoroji inoisirwawo kudivi repamusoro danda chinzvimbo chemuviri weAudi.

Mukuita kwemotokari yemoto welding, laser-arc composite welding ine mukana wekushivirira kwakakura pane imwe laser welding, asi nzvimbo ine hukama yelaser uye arc, laser welding paramita, arc paramita uye zvimwe zvinhu zvinofanirwa kutariswa zvakazara.Iko kupisa uye hukuru hwekufambisa maitiro mu laser-arc welding yakaoma, kunyanya iyo mashandiro esimba rekudzora uye IMC ukobvu uye chimiro chekugadzirisa mune zvakasiyana welding welding haisati yanyatsojeka, uye kumwe kutsvagisa kunodiwa.

Zvimwe zvemotokari muviri laser welding maitiro

Laser yakadzika yekupinda welding, laser waya yekuzadza welding, laser brazing uye laser-arc composite welding uye mamwe maitirwo ewelding zvave zvakanyanya kukura dzidziso uye yakakura inoshanda maapplication.Nekuvandudzwa kweindasitiri yemotokari zvinodikanwa pakuita basa rekushongedza muviri uye kuwedzera kwekudiwa kwezvinhu zvakasiyana-siyana mukugadzira mota dzakareruka, laser spot welding, laser swing welding, multi-laser beam welding uye laser flight welding zvakateererwa. ku.

Laser nzvimbo welding process

Laser spot welding ndeye advanced laser welding tekinoroji, ine zvakanakira kukurumidza welding kumhanya uye yakakwirira welding chaiyo.Nheyo yakakosha yelaser spot welding ndeyekutarisa danda relaser kune imwe nzvimbo pachikamu chinosungirirwa, kuitira kuti simbi iri ipapo inyunguduswe ipapo, nekugadzirisa laser density kuti iwane thermal conduction welding kana yakadzika fusion welding maitiro. , kana laser beam inomira kushanda, iyo simbi yemvura inoyerera, yakasimbiswa kuti iite mubatanidzwa.

Pane nzira mbiri huru dzelaser spot welding: pulsed laser spot welding uye inoenderera mberi laser spot welding.Pulsed laser spot welding laser beam peak simba yakakwira, asi iyo nguva yekuita ipfupi, inowanzo shandiswa magnesium alloy, aruminiyamu alloy uye mamwe mwenje simbi welding.Avhareji simba relaser beam mukuenderera mberi laser spot welding yakakwira, iyo laser chiitiko nguva yakareba, uye inoshandiswa zvakanyanya musimbi welding.

Panyaya yemotokari yemoto welding, kana ichienzaniswa nekushivirira nzvimbo welding, laser spot welding ine zvakanakira kusabatika, nzvimbo welding trajectory inogona kugadzirwa yakazvimiririra, nezvimwe, izvo zvinogona kusangana nezvinodiwa zvemhando yepamusoro welding pasi pemagapu akasiyana epamakumbo. zvinhu zvemuviri zvemotokari.

Laser swing welding process

Laser swing welding ndiyo itsva laser welding tekinoroji yakakurudzirwa mumakore achangopfuura, ayo anga achinetsekana zvakanyanya.Nheyo yeiyi tekinoroji ndeiyi: nekubatanidza boka re galvanometer pane laser welding musoro, iyo laser beam inokurumidza, yakarongeka uye mune diki renji, kuitira kuti iwane mhedzisiro yelaser beam inoenda kumberi ichikurudzira.

Iwo main swing trajectories mune laser swing welding process anosanganisira transverse swing, longitudinal swing, denderedzwa swing uye kusingaperi kuzungunuka.Iyo laser swing welding process ine yakakosha mabhenefiti muwelding yemuviri wemotokari.Pasi pechiito chelaser beam swing, kuyerera kwedziva rakanyungudutswa kunoshandurwa zvakanyanya.Naizvozvo, maitiro acho haangogone kubvisa chikanganiso chisina kuvharwa, kuwana kunatswa kwezviyo uye kudzvanyirira porosity muwelding yeimwe mota yemuviri zvinhu.Uye zvakare, inogona zvakare kuvandudza matambudziko akadai sekusakwana kusanganiswa kwezvinhu zvakasiyana uye kushomeka kwemagetsi zvimiro zve welds mukushongedza kwezvinhu zvakasiyana zvemuviri wemotokari.

Multi-laser beam welding process

Parizvino, iyo optical fiber laser inogona kukamurwa kuita akawanda laser matanda ne splitter module yakaiswa mu welding musoro.Multi-laser beam welding yakaenzana nekushandisa akawanda kupisa masosi muwelding process, nekugadzirisa kugovera kwesimba kwedanda, matanda akasiyana anogona kuita mabasa akasiyana, akadai se: danda rine simba repamusoro ndiro ndiro guru, rinotarisira kudzika. kupinda welding;Iyo yakaderera simba density yedanda inogona kuchenesa uye preheat pamusoro pechinhu, uye kuwedzera kutorwa kwelaser beam simba nezvinhu.

Galvanized yakakwirira-simba simbi zvinhu zvinoshandiswa zvakanyanya mumotokari muviri.Multi-laser beam welding tekinoroji inogona kuvandudza maitiro evaporation yezinc vapor uye hunhu hunosimba hwechidziva chakanyungudutswa mukuita kwekugadzika kwesimbi yesimbi, kunatsiridza dambudziko rekupopota, uye kuwedzera simba rekusimba reweld.

Laser ndege welding process

Iyo laser yekubhururuka welding tekinoroji ndiyo nyowani laser welding tekinoroji, ine yakakwirira welding inoshanda uye inogona kugadzirwa yakazvimirira.Iyo yakakosha musimboti welaser kubhururuka welding ndeyekuti kana laser beam ikaitika paX uye Y magirazi egirazi rekuvheneka, iyo Angle yegirazi inodzorwa neyakazvimiririra chirongwa kuti iwane kutsauka kweiyo laser beam pane chero Angle.

Iyo yechinyakare laser welding yemota muviri inonyanya kutsamira pakufamba kweiyo laser welding musoro inotungamirwa newelding robhoti kuti iwane welding mhedzisiro.Nekudaro, iko kukwenenzverwa kwemuviri wemotokari kwakaganhurirwa zvakanyanya nekudzokorora kudzokororwa kwekufamba kwerobhoti welding nekuda kwehuwandu hukuru hwema welds uye kureba kwehurefu hwewelds.Kusiyana neizvi, laser flight welding inongoda kugadzirisa Angle yegirazi kuti iwane welding mukati meimwe renji.Naizvozvo, laser ndege welding tekinoroji inogona kuvandudza zvakanyanya kunaka kwewelding uye ine tarisiro yakakura yekushandisa.

Pfupiso uye tarisiro

Nekuvandudzwa kweindasitiri yemotokari, remangwana remuviri welding tekinoroji icharamba ichikura muzvinhu zviviri: welding process uye hungwaru tekinoroji.

Muviri wemotokari, kunyanya simba idzva remotokari muviri, uri kusimukira munzira yekureruka.Akareruka alloys, composite zvinhu uye dissimilar zvinhu zvichave zvakanyanya kushandiswa mumotokari muviri, yakajairwa laser welding process inonetsa kuzadzisa zvinodiwa zvewelding, saka yepamusoro-mhando uye inoshanda welding process ichava iyo ramangwana rekusimudzira maitiro.

Mumakore achangopfuura, ari kusimukira laser welding maitirwo, senge laser swing welding, multi-laser beam welding, laser ndege welding, nezvimwewo, anga ari ekutanga theoretical tsvagiridzo uye maitiro ekuongorora maererano nemhando yewelding uye kunyatsoita welding.Mune ramangwana, zvinodikanwa kunyatso sanganisa iyo iri kubuda laser welding process nezvinhu zvakareruka uye zvakasiyana-siyana zvekushongedza zviratidziro zvemuviri wemotokari, kuita tsvakiridzo yakadzama pamusoro pekugadzirwa kwelaser beam swing trajectory, maitiro ekuita kweakawanda-laser beam simba. uye kuvandudzwa kwekushanda kwendege welding, uye ongorora yakura yakareruka kuremerwa kwemotokari muviri welding process.

Iyo laser welding tekinoroji yemuviri wemotokari yakanyatsobatanidzwa nehungwaru tekinoroji.Iyo chaiyo-nguva yekuona kwelaser welding mamiriro emuviri wemotokari uye mhinduro yekudzora yemaitiro paramita inoita basa rakasimba mumhando yewelding.Iyo yazvino yakangwara laser welding tekinoroji inonyanya kushandiswa pre-welding trajectory kuronga uye yekutevera uye post-welding mhando yekuongorora.Kumba nekune dzimwe nyika, iyo tsvakiridzo yekutarisa chirema chekushongedza uye parameter adaptive control ichiri mudanho rekutanga, uye laser welding process parameter adaptive control tekinoroji haina kushandiswa mukugadzira mota muviri.

Naizvozvo, tichifunga nezve mashandisirwo emhando yelaser welding tekinoroji mukuita kwemotokari muviri welding, yakangwara inonzwa sisitimu yelaser welding ine advanced akawanda-sensors seyakanyanya uye yakakwirira-kumhanya uye yakakwirira-chaiyo welding robhoti yekudzora system inofanirwa kuve. yakagadziridzwa mune ramangwana kuve nechokwadi chechokwadi-nguva uye huchokwadi hwese maficha ehungwaru laser welding tekinoroji.Vhura chinongedzo che "pre-welding trajectory planning - parameter adaptive control ye welding quality online kuonekwa after welding" kuti uve nechokwadi chepamusoro-soro uye kushanda zvakanaka.

Nguva yekutumira: Oct-16-2023