Kudiwa kwesimbi munharaunda yemazuva ano kunoramba kuchiwedzera.Muhupenyu hwezuva nezuva, zvinhu zvakawanda zvakagadzirwa nesimbi, uye simbi zhinji haigoni kukandwa panguva imwe chete.Saka, zvinodikanwa kushandisa magetsi welding kuti uwedzere.Basa re electrode mumagetsi welding process yakakosha zvikuru.

Iyo welding tsvimbo ine simba uye yakanyungudutswa pakupisa kwepamusoro panguva yearc welding, uye inozadza majoini eiyo welding workpiece.Kazhinji, iyo inoenderana electrode inosarudzwa maererano neyakagadzirwa welding workpiece.Welding tsvimbo inogona kushandiswa kupinza mhando imwe chete yesimbi kana welding pakati pesimbi dzakasiyana.

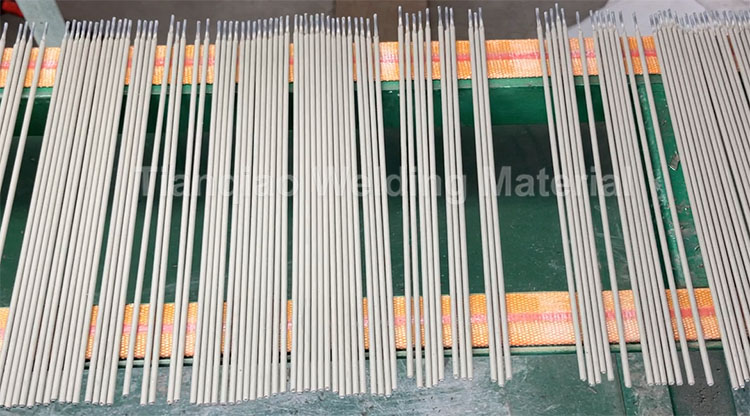

Chimiro cheWelding Electrode

Iyo yemukati yesimbi yepakati ye welding tsvimbo uye yekunze kwekuvhara inoumbwa.The welding core isimbi yesimbi ine imwe dhayamita uye kureba.Basa guru reiyo welding core ndeyekuitisa ikozvino kupisa uye kunyungudika, uye kuzadza nekubatanidza workpiece.

Iyo yepakati zvinhu inoshandiswa pakushongedza inogona kukamurwa kuita kabhoni simbi, alloy simbi uye simbi isina tsvina.Zvisinei, kuitira kuti usangane nezvinodiwa zvekushongedza, pane zvakakosha zvinodikanwa zvezvinhu uye simbi zvinhu zvemukati welding, uye kune mitemo yakasimba pane zviri mukati mezvimwe zvinhu zvesimbi.Nekuti iyo simbi inoumbwa yewelding core ichakanganisa zvakananga kunaka kweiyo weld.

Ikoko pachava nemucheka wekuputira kunze kwe electrode, iyo inonzi flux coat.Flux jasi rinoita basa rakakosha.Kana yemagetsi welding musimboti inoshandiswa zvakananga weld workpiece, mhepo uye zvimwe zvinhu zvichapinda simbi yakanyungudutswa yemagetsi welding musimboti, uye kemikari kuita kuchaitika musimbi yakanyungudutswa kuti zvakananga kukonzera weld.Matambudziko emhando senge pores uye makatsemuka anozokanganisa kusimba kwewelding.Flux jasi rine zvakakosha zvinhu zvinoora uye kunyunguduka kuita gasi uye slag pane yakanyanya tembiricha, iyo inogona kunyatso kudzivirira mweya kupinda nekuvandudza welding mhando.

Izvo zvinongedzo zvejasi reflux zvinosanganisira: hydrochloric acid, fluoride, carbonate, oxide, organic matter, iron alloy uye mamwe makemikari poda, nezvimwe, zvakasanganiswa zvinoenderana neimwe formula reshiyo.Iyo yekuputira yemhando dzakasiyana dze electrode coatings zvakare yakasiyana.

Kune marudzi matatu akajairika, anoti slag agent, gasi generating agent, uye deoxidizer.

Iyo slag agent isanganiswa inogona kuchengetedza simbi yakanyungudutswa kubva kumhepo ingress kana electrode yakanyunguduka, nokudaro ichivandudza kunaka kwewelding.

Iyo gasi inogadzira agent inonyanya kuumbwa nestarch nehupfu hwehuni uye zvimwe zvinhu, izvo zvine kumwe kuderedzwa.

Iyo deoxidizer inoumbwa neferro-titanium uye ferromanganese.Kazhinji, zvinhu zvakadaro zvinogona kuvandudza kusamira kwekupfeka uye kusagadzikana kwekuora kwesimbi.

Mukuwedzera, kune mamwe marudzi ekuputira pamusoro pe electrode pamusoro, uye kuumbwa uye chiyero chemhando imwe neimwe ichave yakasiyana.

Kugadzira nzira ye welding electrode

Nzira yekugadzira ye welding tsvimbo ndeyekugadzira welding core uye kugadzirira kupfekedza maererano nezvinodiwa zvekugadzirwa kwetsvimbo ye welding, uye kuisa iyo yakavharidzirwa zvakafanana pane welding core kuti iite kuti isangane nezvinodiwa zvekugadzirwa kweiyo inokwanisa welding tsvimbo.

Kutanga, simbi yakakungurutswa inobviswa kubva kune coiler, ngura iri pamusoro pesimbi yesimbi inobviswa mumushini, uye inobva yatwasuka.Muchina unocheka simbi yesimbi kusvika pakureba kwe electrode.

Zvadaro, kuvhara kunoda kugadzirirwa pamusoro pe electrode.Zvinhu zvakasiyana-siyana zvakasvibirira zvekuputira zvinosefa kubvisa tsvina, uye zvino inodururwa mumushini maererano nehuwandu, uye binder inowedzerwa panguva imwe chete.Zvese zvehupfu zvehupfu zvinonyatsosanganiswa nekuzunguza kwemuchina.

Isa hupfu hwakasanganiswa muforoma uye woidzvanya mucylindrical cylinder ine denderedzwa gomba pakati.

Isa madhiramu akawanda akadzvanywa mumushini, isa masimbi emagetsi zvakatsetseka mumuchina wekudyisa chiteshi, iwo emagetsi macores anopinda muchina kubva kumuchina wemuchina wekudyara, uye iwo wedling cores anopfuura nepakati pedhiramu nekuda kwekuwedzeredza.Muchina uyu unowaridza hupfu pamusimboti unopfuura kuti ive jasi.

Munguva yekuputira yetsvimbo yewelding, iyo yose yesimbi yakashongedzwa yakafukidzwa nejira rekuvhara.Kuti electrode iite nyore kusungirira uye kuitisa magetsi, musoro nemuswe we electrode zvinoda kukwenenzverwa kubva pajasi kuti ibudise pachena welding core.

Mushure mekuputira, musoro wekukuya uye tsvimbo yemoto mushure mekugaya muswe ichave yakarongeka zvakaenzana pamapuranga esimbi uye inotumirwa kuchoto kuti iome.

Kuti zvikwanise kusiyanisa zviri nyore zvinotsanangurwa uye mienzaniso ye electrode, zvakakosha kudhinda pane electrode.Kana iyo welding tsvimbo inofamba pabhandi rekutakura, electrode yega yega inodhindwa nerabha kudhinda roller pabhandi rekutakura.

Mushure meiyo welding rod modhi yakadhindwa, iyo welding tsvimbo inogona kuiswa uye kutengeswa mushure mekupfuura kuongororwa.

Tianqiao brand welding electrode ine mashandiro akanaka, yakagadzikana mhando, inoyevedza welding kuumbwa, uye yakanaka kubvisa slag, kugona kurwisa ngura, Stomata uye kutsemuka, yakanaka uye yakagadzikana yakaiswa simbi mechanics mavara.Tianqiao brand welding zvinhu zvinosangana nevatengi 'kugamuchirwa noushamwari nekuda kwemhando yepamusoro, kuita kwakanakisa uye mutengo wemakwikwi.Dzvanya panokuona zvakawanda pamusoro pezvigadzirwa zvedu

Nguva yekutumira: Sep-03-2021