Simba rinobva kubrazing rinogona kuve kemikari reaction heat kana isina kunanga kupisa simba.Inoshandisa simbi ine nzvimbo yakanyunguduka yakaderera pane iyo yezvinhu zvinosungirirwa se solder.Mushure mekupisa, solder inonyunguduka, uye capillary chiito chinosundira solder mukati memukana pakati pematanho ekusangana kwejoint kuti inyorove pamusoro pesimbi kuti isungirwe kuitira kuti chikamu chemvura uye chikamu chakasimba zviparadzaniswe.Kupindirana pakati pezvikamu kuita chibatanidza chakasungwa.Naizvozvo, brazing isimba-chikamu uye liquid-phase welding nzira.

1. Hunhu uye kushandiswa kwebrazing

Brazing inoshandisa alloy ine nzvimbo yekunyunguduka yakaderera pane iyo ye base simbi se solder.Kana ichipisa, solder inonyunguduka uye inozadza uye inoramba iri mugomba rejoint nekunyorova uye capillary chiito, nepo simbi yepasi iri munzvimbo yakasimba, ichitsamira pane yemvura solder uye yakasimba base Kupindirana pakati pezvishandiso zvinogadzira mubatanidzwa wakasungwa.Brazing haina mhedzisiro pane zvemuviri uye zvemakemikari zvimiro zve base simbi, kushoma welding kusagadzikana uye deformation, inogona weld dissimilar simbi ine misiyano mikuru yezvivakwa, inogona kupedzisa akawanda welds panguva imwe chete, kutaridzika kwejoinhi kwakanaka uye kwakarongeka, midziyo iri nyore, uye mari yekugadzira idiki.Nekudaro, iyo brazed joint ine simba rakaderera uye kushomeka kwekudzivirira kupisa.

Zvishandiso: Carbide yekucheka maturusi, mabhiti ekuchera, bhasikoro mafuremu, kupisa kunopisa, makonditi uye midziyo yakasiyana-siyana, nezvimwewo;mukugadzira microwave waveguides, erekitironi machubhu uye emagetsi vacuum zvishandiso, brazing ndiyo chete nzira inogoneka yekubatanidza.

2.Brazing metal uye flux

Brazing filler simbi ndiyo simbi yekuzadza iyo inoumba musoro wekubhuroka, uye mhando yemusoro wekubhuroka inotsamira pane brazing filler simbi kusvika pamwero mukuru.Iyo yekuzadza simbi inofanirwa kuve neyakafanira kunyunguduka, yakanaka kunyorova uye kugona kukonzeresa, inogona kuparadzaniswa nesimbi yepasi, uye inofanirwa kunge iine zvimwe zvemichina zvimiro uye zvemuviri uye zvemakemikari zvimiro kuti zvisangane nekuita zvinodiwa zvejoint.Zvinoenderana neyakasiyana yekunyungudika yebrazing filler simbi, brazing inogona kukamurwa kuita mapoka maviri: yakapfava brazing uye yakaoma brazing.

(1) Kupfava.Brazing ine nzvimbo yekunyungudika pazasi 450 ° C inonzi yakapfava brazing, uye inowanzoshandiswa brazing filler simbi itin lead brazing, ine yakanaka kunyorova uye conductivity yemagetsi uye inoshandiswa zvakanyanya muzvigadzirwa zvemagetsi, midziyo yemotokari uye zvikamu zvemotokari.Simba rejoint yakasungwa rinowanzo 60 ~ 140MPa.

(2) Kubhuya.Brazing ine nzvimbo yakanyunguduka yakakwira kupfuura 450 ° C inonzi brazing, uye zvakajairika brazing zvinhu indarira uye sirivheri base brazing zvinhu.Iyo yakabatana ine sirivheri base yekuzadza simbi ine simba rakawanda, magetsi conductivity uye corrosion resistance, nzvimbo inonyunguduka yesimbi yekuzadza yakadzikira, uye maitiro acho akanaka, asi mutengo wesimbi yekuzadza wakakwira, uye inonyanya kushandiswa kugadzira. zvikamu zvine zvinodiwa zvepamusoro.Brazing inonyanya kushandiswa simbi uye mhangura alloy workpieces nemasimba makuru, uye nemidziyo yekushongedza.Brazed yakabatana simba re200 ~ 490MPa,

Ongorora: Iyo yekusangana pamusoro peiyo base zvinhu inofanirwa kuve yakachena kwazvo, saka iyo flux inofanirwa kushandiswa.Basa reiyo flux kubvisa oxide nemafuta kusvibiswa pamusoro pesimbi yepasi uye simbi inozadza, chengetedza iyo inobatana pamusoro pesimbi yekuzadza uye base simbi kubva kune oxidation, uye kuwedzera kunyorova uye capillary fluidity yekuzadza. simbi.Iko kunyunguduka kwekuyerera kunofanirwa kuve kwakaderera pane iyo yesimbi yekuzadza, uye kukora kweiyo inoyerera yakasara kune base simbi uye majoini kunofanirwa kuve kushoma.Iyo yakajairika brazing flux ndeye rosin kana zinc chloride mhinduro, uye yakajairika brazing flux musanganiswa weborax, boric acid uye alkaline fluoride.

Zvinoenderana neakasiyana kupisa masosi kana nzira dzekudziya brazing inogona kukamurwa kuita:murazvo wemoto, induction brazing, choto chemoto, dip brazing, kuramba brazing uye zvichingodaro.Nekuti tembiricha yekudziya yakadzikira panguva yekubhuroka, haina pesvedzero shoma pakuita kweiyo workpiece zvinhu, uye kusagadzikana deformation ye weldment zvakare idiki.Zvisinei, kusimba kwejoints yebrazed kunowanzo kuderera, uye kupisa kwekudzivirira hakuna kunaka.

Brazing Heating nzira:Anenge ese anopisa masosi anogona kushandiswa senge brazing kupisa sosi, uye zvinoenderana neizvi brazing inoiswa.

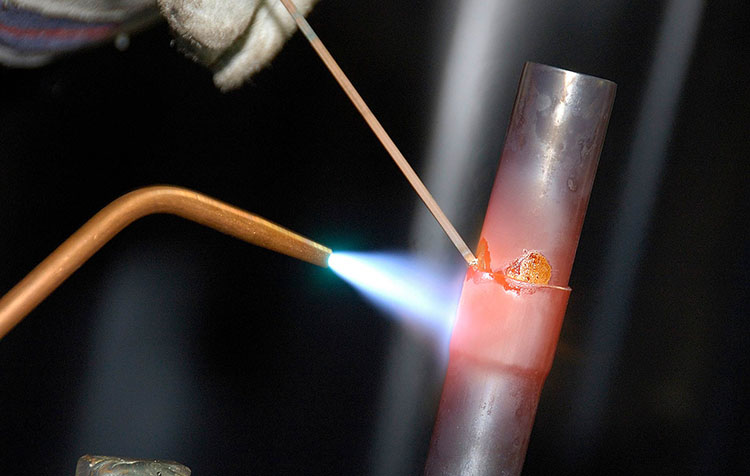

Kupisa moto:kupisa nemoto wegasi, inoshandiswa kugadzira simbi yekabhoni, simbi isina tsvina, carbide, simbi yakakandwa, mhangura nemhangura alloys, aluminium uye aluminium alloy brazing.

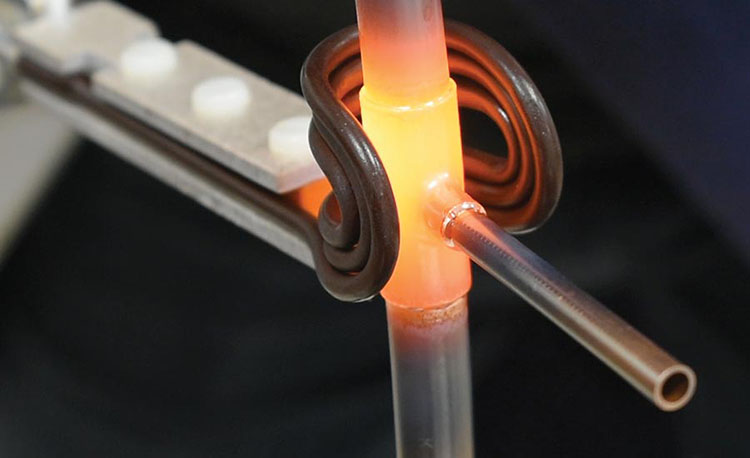

Induction brazing:Iko kushandiswa kwealternating magineti minda kugadzira iyo induced ikozvino muchikamu chekudzivirira kupisa kupisa welding, kune symmetrical chimiro chewelding, kunyanya kubhuroka kwepombi shaft.

Dip brazing:iyo welding chikamu inonyudzwa zvishoma kana kuti yakanyura munyundo yakanyungudutswa musanganiswa kana solder kunyungudika, ichivimba nekupisa kweiyi midhiya yemvura kuti iwane brazing process, iyo inoratidzirwa nekukurumidza kupisa, yunifomu tembiricha, diki deformation yewelding chikamu.

Furnace brazing:Iwo welds anopiswa nevira rekudzivirira, iro rinogona kuchengetedza welds nekupukuta kana kushandisa kuderedza kana inert magasi.

Pamusoro pezvo, kune solder iron brazing, kuramba brazing, diffusion brazing, infrared brazing, reaction brazing, electron beam brazing, laser brazing, nezvimwe.

Brazing inogona kushandiswa kugadzira kabhoni simbi, simbi isina tsvina, superalloy, aruminiyamu, mhangura uye zvimwe zvinhu zvesimbi, uye zvakare inogona kubatanidza simbi dzakasiyana, simbi uye dzisiri simbi.Inokodzera welding majoini ane mutoro mudiki kana kushanda pakamuri tembiricha, kunyanya yakakodzera kune chaiyo, micro uye yakaoma multi-brazed welds.

Nguva yekutumira: Jul-06-2023