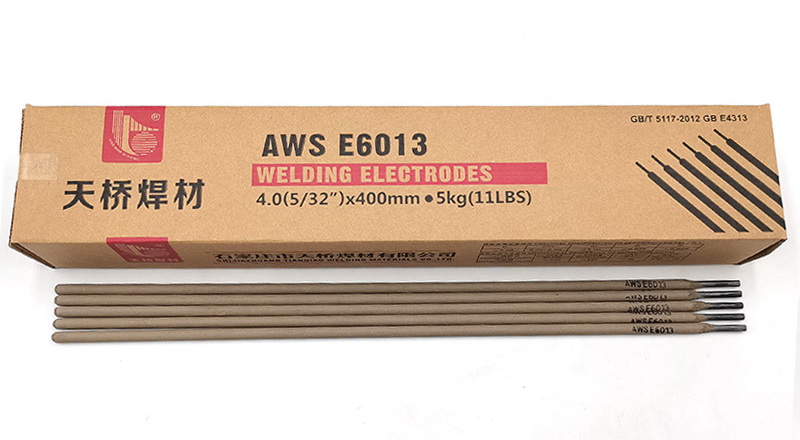

Q1: Chii chinonzi welding zvinhu?Chii chingasanganisira?

Mhinduro: Welding zvinhu zvinosanganisira welding tsvimbo, welding waya, fluxes, magasi, electrodes, gaskets, etc.

Q2: Chii chinonzi acid electrode?

Mhinduro: Kuputira kweasidhi electrode ine yakawanda yeasidhi oxides yakadai seSiO2, TiO2 uye imwe chiyero che carbonate, uye alkalinity ye slag iri pasi pe 1. Titanium electrodes, calcium titanium electrodes, ilmenite electrodes uye iron oxide. maelectrodes ese ane acid electrode.

Q3: Chii chinonzi alkaline electrode?

Mhinduro: Alkaline electrode coating ine yakawanda yealkaline slag-forming zvinhu zvakadai semarble, fluorite, nezvimwewo, uye ine imwe chiyero che deoxidizer uye alloying agent.Low-hydrogen mhando electrodes ari alkaline electrodes.

Q4: Chii chinonzi cellulose electrode?

Mhinduro: Iyo electrode coating ine yakakwira cellulose yemukati uye yakagadzikana arc.Iyo inoora uye inogadzira huwandu hwakawanda hwegasi kuchengetedza weld simbi panguva yewelding.Mhando iyi ye electrode inoburitsa zvishoma slag uye iri nyore kubvisa.Inonzi zvakare vertical downward welding electrode.Inogona kuve yakashongedzwa munzvimbo dzese, uye vertical welding inogona kusungirirwa pasi.

Q5: Nei electrode ichifanira kuomeswa zvakasimba isati yatungidzirwa?

Welding tsvimbo dzinowanzo kanganisa maitiro ekuita nekuda kwekunyorova kwehunyoro, zvichikonzera kusagadzikana kwearc, kuwedzera spatter, uye nyore kugadzira pores, kuputika uye kumwe kukanganisa.Nokudaro, tsvimbo yemoto inofanira kuomeswa zvakasimba isati yashandiswa.Kazhinji, tembiricha yekuomesa yeasidhi electrode i150-200 ℃, uye nguva i1 awa;tembiricha yekuomesa yealkaline electrode ndeye 350-400 ℃, nguva yacho 1-2 maawa, uye yakaomeswa uye yakaiswa muincubator pa100-150 ℃ Mukati, tora iyo sezvaunoenda.

Q6: Chii chinonzi welding waya?

Mhinduro: Isimbi yesimbi inoshandiswa sesimbi yekuzadza panguva yewelding uye inoshandiswa kuitisa magetsi panguva imwechete inonzi welding wire.Kune marudzi maviri: waya yakasimba uye flux-cored wire.Inowanzo shandiswa yakasimba welding waya modhi: (GB-yenyika chiyero cheChina) ER50-6 (kirasi: H08Mn2SiA).(AWS-American Standard) ER70-6.

Q7: Chii chinonzi flux cored welding waya?

Mhinduro: Rudzi rwewaya yewelding yakagadzirwa nesimbi yakatetepa mitsetse yakamoneredzwa kuita pombi dzesimbi dzakatenderedzwa uye dzakazadzwa nerumwe rudzi rwehupfu.

Q8: Sei iyo flux cored wire yakachengetedzwa nekabhoni dioxide gasi?

Mhinduro: Kune marudzi mana e flux-cored welding wire: acidic flux-cored gas shielded welding wire (titanium type), alkaline flux-cored gas shielded welding wire (titanium calcium type), metal powder type flux-cored gas shielded welding wire. uye flux-cored self-shield welding waya.Iyo yemba titanium mhando flux-cored gasi shielded welding waya inowanzochengetedzwa ne CO2 gasi;dzimwe flux-cored welding waya dzinodzivirirwa negasi rakasanganiswa (ndapota tarisa kune flux-cored waya yakatarwa).Iyo metallurgical reaction yegasi slag formula yakasiyana, ndapota usashandise zvisirizvo kudzivirira gasi.Flux-cored welding waya gasi slag yakasanganiswa kudzivirira, yakanaka welding seam kuumbwa, yakakwira yakazara michina zvivakwa.

Q9: Nei paine tekinoroji zvinodiwa pakuchena kwekabhoni dhaimoni gasi?

Mhinduro: Kazhinji, CO2 gasi ndeye-chigadzirwa chekugadzirwa kwemakemikari, nekuchena kunosvika 99.6%.Iine zvisaririra zvetsvina uye unyoro, izvo zvinounza kuremara senge pores kune weld.Pamusoro pezvigadzirwa zvakakosha zvewelding, gasi rine CO2 kuchena ≥99.8% inofanira kusarudzwa, ine pores shoma mu weld, yakaderera hydrogen content, uye yakanaka crack resistance.

Q10: Sei uine yakakwirira tekinoroji zvinodiwa kune argon kuchena?

Mhinduro: Ikozvino kune marudzi matatu eargon pamusika: plain argon (kuchena kwakapoteredza 99.6%), argon yakachena (kuchena kwakapoteredza 99.9%), uye yakakwirira-kuchena argon (kuchena 99.99%).Iwo maviri ekutanga anogona kugadzirwa kune kabhoni simbi uye Stainless simbi.Yakakwirira-kuchena argon inofanira kushandiswa pakunama simbi dzisina ferrous dzakadai sealuminium nealuminium alloys, titanium uye titanium alloys;kuti udzivise oxidation ye weld uye inopisa-yakakanganiswa nzvimbo, yakakwirira-yemhando uye yakanaka weld kuumbwa haigone kuwanikwa.

Nguva yekutumira: Jun-23-2021