Munguva yekubatanidza welding, pasi pekuita kwewelding heat source, chikamu chesimbi chemvura chine chimwe chimiro chejometri chakaumbwa pane weldment nesimbi yakanyungudutswa yeelectrode uye chidimbu chesimbi yakanyungudutswa ndiro dziva rakanyungudutswa.Mushure mekutonhodza, inova weld, saka tembiricha yedziva yakanyungudutswa inokanganisa zvakananga kunaka kwewelding.

Kana tembiricha yedziva yakanyungudutswa yakakwira, dziva rakanyungudutswa rakakura, uye simbi yakanyungudutswa ine fluidity yakanaka, iyo fusion zone iri nyore kusanganisa;asi kana tembiricha yanyanya, simbi yakanyungudutswa iri nyore kudonha, uye divi rekuseri kwe-single-sided welding uye kaviri-side kuumba zviri nyore kupisa nepakati, kuita mabumps e weld, uye chimiro.Izvo zvakaoma kudzora, uye plastiki yejojo inoderedzwa, uye mubatanidzwa uri nyore kuputika;kana tembiricha yedziva yakanyungudutswa yakadzikira, dziva rakanyungudutswa riri diki, simbi yakanyungudutswa inenge yasviba, uye mvura yacho yakashata.Zviri nyore kuburitsa kukanganisa kwakadai sekupinda kusina kukwana, kushaya fusion, uye slag kubatanidzwa.

Naizvozvo, kunyatso kudzora tembiricha yedziva yakanyungudutswa kwakakosha kuve nechokwadi chekuita welding uye kunaka kwechigadzirwa chakapedzwa.

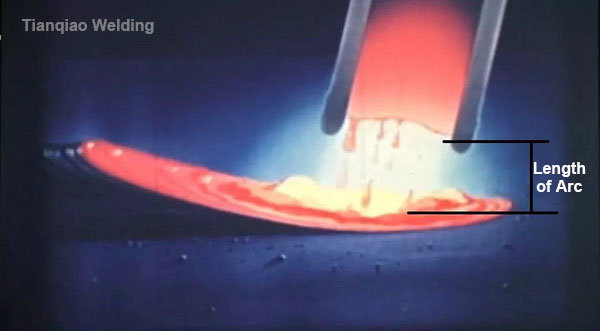

Mufananidzo 1 Tianqiao welding

Kupisa kwedziva rakanyungudutswa kwakabatana zvakanyanya neazvino welding, dhayamita ye electrode, nzira yekufambisa, kona ye electrode, uye arc yekupisa nguva.Matanho anotevera anotorwa kuti adzore kudziya kwedziva rakanyungudutswa zvichienderana nezvakakodzera.

1. Welding ikozvino uye electrode dhayamita

Aya maviri maficha zvinhu zvakakosha zvewelding, uye izvo zviviri zvakare zvine chisungo chisinga patsanuke.Munguva yekubatanidza welding, iyo ikozvino inoyerera ichidzokera kuburikidza neweldment inonzi welding current.Iyo dhayamita ye electrode inoreva kuyambuka-chikamu saizi yesimbi yekuzadza tsvimbo.Mumashoko akareruka, kana iyo welding tsvimbo inogona kunyungudutswa zvakanaka inotarirwa nezvino yakapfuura.

Kana ikozvino iri duku, zvakaoma kutanga arc, electrode iri nyore kunamatira kune weldment, zviyero zvehove zvakakora, uye mativi maviri haana kusanganiswa;kana ikozvino yakakura zvikuru, kupfapfaidza uye utsi panguva yekuputika kuchava kukuru, electrode ichava yakatsvuka, uye pamusoro pedziva rakanyungudutswa richava rakajeka zvikuru.Zviri nyore kupisa nepakati uye undercut;kana yazvino yakafanira, zviri nyore kubatidza uye arc yakagadzikana, kupfachuka kudiki, yunifomu yekurira inonzwika inogona kunzwika, mativi maviri emusono we welding anonyatso kuchinjika kune hwaro zvinhu, mazero ehove epamusoro akanyanya. mutete, uye welding slag iri nyore Knock kunze.Maererano nekushandiswa kwayo, kune hukama hwakaoma.

1.1 Sarudza welding ikozvino uye electrode dhayamita zvichienderana nenzvimbo yenzvimbo yeweld

Munzvimbo dzakasimukira, dzakachinjika uye dzakatwasuka, yazvino idiki zvakada kufanana neiyo yeflat welding, uye yazvino inofanira kuwanzoita 10% idiki pane iyo yeflat welding.

Saizvozvo, munzvimbo dzakamira, dzakachinjika, uye dzakatwasuka, dhayamita ye electrode kazhinji idiki pane iyo yeflat welding.Semuenzaniso, mu flat welding ye flat plate yakakura kudarika 12mm, iyo 5.0mm electrode inowanzoshandiswa., Uye pane inenge isina electrode ine dhayamita ye5.0mm munzvimbo dzakamira, dzakachinjika uye dzakatwasuka.

1.2 Iyo welding ikozvino uye electrode dhayamita inosarudzwa maererano neiyo welding level ye weld.

Semuenzaniso, ye12mm flat plate butt joints, 3.2mmTianqiao electrodesanowanzo shandiswa kune yepasi layer ye flat welding, uye welding ikozvino i90-110A, uye 4.0mm.Tianqiao electrodesinogona kushandiswa pakuzadza uye kuvhara layer, uye welding ikozvino 160-175A.

Naizvozvo, kusarudzwa kunonzwisisika kweiyo welding ikozvino uye dhayamita ye electrode inogona kudzora zviri nyore tembiricha yedziva rakanyungudutswa, inova hwaro hwekuumbwa kwakanaka weld.Kana iyo welding ikozvino iri diki, tembiricha ye weld pool yakadzikira zvakanyanya, zvichiita kuti arc ive isina kugadzikana, uye workpiece inogona kunge isina welded kuburikidza.Kana iyo welding current yakakwira zvakanyanya uye tembiricha yedziva yakanyungudutswa yanyanya kukwira, zvinokonzeresa kupfachuka kwakakomba uye kuyerera kwesimbi yakanyungudutswa, uye kunyange kupisa kuburikidza neworkpiece kuita welding bead.

Ukama huri pakati peiyo welding ikozvino uye dhayamita ye electrode yakanyorwa pazasi.Iwe unogona kuita sarudzo ine musoro zvichienderana neruzivo rwako kana maitiro.Iwe haufanire kuona iwo maparamendi akafanana nevamwe, chero iwe uchingonzwa kuti akakodzera uye simbisa yakanaka weld kuumbwa.

2. Kutakura kwe welding tsvimbo

Thewelding tsvimboinodyiswa munzira yedziva rakanyungudutswa paaxis.Mushure mokunge tsvimbo yemoto yakanyungudutswa, urefu hwearc hunogona kuramba huchichengetwa.Naizvozvo, kumhanya kwetsvimbo yewelding mugwara redziva rakanyungudutswa rinodiwa kuti rienzane nekunyunguduka kwetsvimbo yewelding.

Kana kukurumidza kwekudya kwe electrode kwakaderera kudarika kunyunguduka kwe electrode, kureba kwearc kunowedzera zvishoma nezvishoma, zvichiita kuti arc avhiringidze;kana kukurumidza kwekudya kwe electrode kwakanyanyisa, kureba kwearc kuchapfupiswa nokukurumidza, uye kupera kwe electrode kuchave kupfupi-kutenderera kunosangana ne weldment.Kudzima arc.

Mufananidzo 2 Tianqiao welding

3. Angle yekuendesa uye nzvimbo yekudya

Munguva yewelding, kona ye electrode inofanira kuchinja nechinzvimbo chewelding, uye nguva dzose chengetedza tembiricha yedziva rakanyungudutswa kumativi ose emupendero wakashata wakakodzera.Kana kutonhora kwakanyanya, kunokonzera kupisa-kuburikidza, uye kana yakanyanya kuderera, inokonzera chiitiko chekusakwana kwekupinda uye fusion.Kana kona iri pakati pe electrode uye kutungamira kwewelding iri madhigirii makumi mapfumbamwe, iyo arc inonangana uye tembiricha yedziva yakanyungudutswa yakakwirira;

Kana kona ikava diki, arc inoparadzirwa uye tembiricha yedziva rakanyungudutswa richadzikira.Semuyenzaniso, kana yepasi layer ye12mm flat welding chisimbiso, kana welding rod angle iri 50-70 madhigirii, tembiricha yedziva yakanyungudutswa ichadzikiswa panguva ino, uye chiitiko chewelding bead kana kusimuka kudivi rekuseri. inodziviswa.Kune mumwe muenzaniso, mushure mekushandura tsvimbo yewelding pazasi pe 12mm plate vertical welding seal, tinoshandisa 90-95 degree welding rod angle pakutakura tsvimbo yewelding, kuitira kuti tembiricha yedziva rakanyungudutswa rikurumidze kuwedzera. gomba rakanyungudutswa rinogona kuvhurwa zvakanaka, uye nzvimbo yekuseri inoumbwa yakati sandarara, iyo inogona kunyatsodzorwa.Chiitiko chekuti iyo yejoint point is concave.

Kana iyo electrode feed chinzvimbo isina kukwana, inokonzeresa kusakwana kwekupinda kana groove clamping.Nemhaka yokuti arc inenge yakapararira panguva ino, kunyunguduka kwekunyunguduka kwemucheto usina kujeka wezvinhu zvepasi hakuna kukwana, zvichiita kuti kusakanganiswa kwezvinhu zvepasi pasi;kana iwe uchida kunyungudutsa zvakakwana simbi, unofanira kuwedzera nguva yekunyunguduka.Welding, yakawanda-layer superposition yeakanyungudutswa dziva inoburitsa slag inclusion phenomenon.

Nzira chaiyo ndeyekutambanudza tsvimbo yemoto mugororo rakagomara pakona ye75 madhigirii, gadzirisa groove base zvinhu kuti zvinyunguduke uye zvizungunuke kumativi ose, chiito chega chega chinotora sekondi imwe, kusvika ikozvino dziva rekutanga rakanyungudutswa rinoumbwa, wozopinda mune inotevera Kuumbwa kwedziva rakanyungudutswa.Panguva ino, nguva yekunyunguduka yedziva rimwe nerimwe rakanyungudutswa ipfupi uye uremu hwakareba, uye hahuna kukodzera kukonzeresa kudonha, uye bundu rewelding haringagadziri.Iyo isina kudzika groove zvakare inobatsira kune welding yenzvimbo yekuvhara.

Dziva rekupedzisira rakanyungudutswa rinovhara 2/3 yerimwe rapfuura.Dziva rega rega rakanyungudutswa rakatetepa, uye rekupedzisira rinoita kunyunguduka kwepashure-kupisa pane rakapfuura, kuve nechokwadi kuti gasi riri mudziva rakanyungudutswa rine nguva yakakwana yekupfachukira nekuridzivirira kubva pakugadzirwa.Stomata.

Mufananidzo 3 Tianqiao welding

4. Arc kupisa nguva

Muchiito chekudzidzisa kweyakadzika uye yakatwasuka yakagadziriswa welding ye57 × 3.5 pombi, iyo arc-breaking nzira inoshandiswa pakushongedza.Paunotanga welding, kutonhora kwesimbi yepasi kwakaderera.Kana iyo welding tsvimbo isina kuiswa kumucheto kwegorofu, simbi yakanyungudutswa ichakurumidza kuderera kumashure uye inogadzira undercuts.Iyo weld formation ichavawo yakakwira uye yakamanikana, iyo isingazoite mhedzisiro yekunyanyisa kutsetseka, uye zviri nyore Iyo inoguma pamusoro haina kusanganiswa.

Kuongorora kubva pachimiro chedziva rakanyungudutswa, kana riri muchimiro chedonhwe rinodonha, chimiro che welded hachina kunaka, uye welding bead inogona kuitika.Naizvozvo, iyo welding poindi inofanirwa kuve yakanyatso preheated kubva kumusoro welding.Kona pakati pe electrode nepombi i75 degrees.Mushure mekunge arc yatungidzwa, iyo arc inotambanudzirwa kuti itange kupisa.Mushure mekudonha kwekutanga kwesimbi yakanyungudutswa pamusoro we electrode inodonha, iyo electrode inotumirwa mukati.

Kupisa kwedziva rakanyungudutswa panguva ino kunofanirwa kuve nechokwadi chekuti saizi yedziva yakanyungudutswa ndiyo hupamhi hwegorofu pamwe ne1 mm, kuitira kuti chigadziko chinyatsonyungudika mudonhwe kuita weld.

Mukushanda kwechigadzirwa chewelding, zvakakosha kuti udzidze kutarisa kuchinja kwekushisa kwedziva rakanyungudutswa uye kugona nzira yekudzora zvinobudirira kupisa kwedziva rakanyungudutswa, rinova hwaro hwekudzidza welding tekinoroji.Izvo zvinodiwa kuti ukwanise kutonga iyo welding tsvimbo angle, nzvimbo yekudyisa uye nguva yekunyunguduka zvinoenderana nedziva rakanyungudutswa rechikamu chimwe nechimwe, nekukurumidza kubata tekinoroji yekushanda yezvikamu zvakakosha zvakati wandei, uye mushure menguva yekudzidziswa chaiko, iyo tekinoroji nhanho inovandudza. nokukurumidza, uye kuitika mwero zvakasiyana-siyana welding kuremara Zvinonyanya kuderera, kunatsiridza strain simba muzvakaoma kuvaka welding, izvo zvinobatsira kuvandudza welding tekinoroji mune ramangwana.

Nguva yekutumira: Jul-15-2021