Riniwelding simbi isina tsvina, kushanda kwe electrode kunofanira kufanana nechinangwa chesimbi isina tsvina.Stainless simbi electrode inofanirwa kusarudzwa zvinoenderana nesimbi yepasi uye mamiriro ekushanda (kusanganisira tembiricha yekushanda, yepakati yekubata, nezvimwewo).

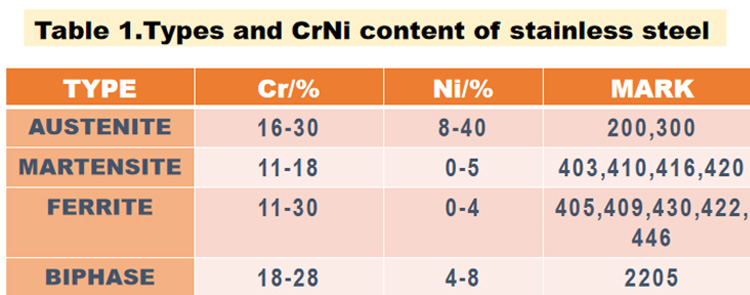

Mhando ina dzesimbi isina tsvina pamwe chete nealloying zvinhu zvinoshandiswa

Simbi isina simbi inogona kukamurwa kuita mhando ina: Austenitic, martensitic, ferritic uye biphase Stainless simbi, sezvinoratidzwa muTebhurari 1.

Izvi zvinobva pane metallographic chimiro chesimbi isina tsvina pane tembiricha yekamuri.Kana simbi yakapfava ichidziya1550° F, chimiro chinoshanduka kubva mukamuri-tembiricha ferrite chikamu kuenda kune austenitic chikamu.Kana yatonhodzwa, chimiro chesimbi chakapfava chinoshandurwa zvakare kuita ferrite.Austenitic zvimiro zviripo pakupisa kwepamusoro hazvisi-magnetic uye zvine simba shoma uye kusimba pane kamuri-tembiricha ferrite zvimiro.

Nzira yekusarudza yakakodzera Stainless steel welding material?

Kana iyo base material yakafanana, mutemo wekutanga ndewe "match the base material".Semuenzaniso, sarudza welding zvinhu zve310 or 316simbi isina ngura.

Kune welding dissimilar materials, chiyero chekusarudza base material ine yakakwira alloying element inoteverwa.Semuenzaniso, kana 304 kana 316 simbi isina tsvina yakashongedzwa, sarudza rudzi316.

Asi kunewo akawanda asingateveri "matching base material" musimboti wemamiriro akakosha, saka zvinodikanwa "kubvunza tafura yekusarudza welding".Somuenzaniso, mhando304simbi isina tsvina ndiyo yakajairika base simbi, asi hapana Type304electrode.

Kana iyo welding inofananidzwa neyakagadzika zvinhu, ungasarudza sei welding zvinhu kuti weld304simbi isina ngura?

Kana welding304simbi isina tsvina, shandisa mhando308welding zvinhu, nekuti izvo zvekuwedzera zvinhu mukati308simbi isina tsvina inogona kudzikamisa zviri nani nzvimbo yeweld.

308L zvakare isarudzo inogamuchirwa.L zvinoreva low carbon content,3XXL simbi isina kabhoni yemukati ≤0.03%, uye mwero3XXStainless simbi inogona kuva kusvika0.08%carbon content.

Nekuda kwekuti welding yakaita L ndeyemhando imwechete yekuisa mucherechedzo seusina-L-shaped welding, vagadziri vanofanirwa kukoshesa kushandisa L-shaped welding nekuti iyo yakaderera kabhoni yemukati inodzikisira tsika ye intergranular corrosion (ona Mufananidzo 1).

Nzira yekugadzira simbi isina tsvina uye kabhoni simbi?

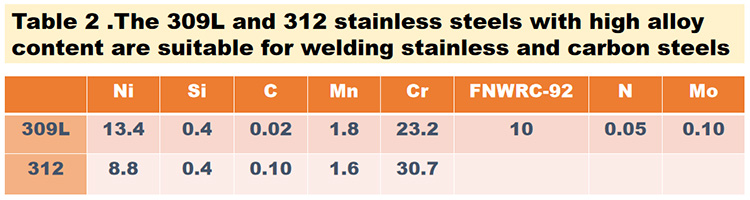

Kuti uderedze mutengo, zvimwe zvimiro zvinopinza dhizaini yekupokana nepamusoro pekabhoni simbi.Paunenge uchiswededza base material isina alloying zvinhu zvine base material ine alloying elements, shandisa welding material ine yakakwira alloying content kudzikamisa dilution rate muweld.

Kana welding kabhoni simbi ne304 or 316simbi isina tsvina uye mamwe akasiyana simbi isina tsvina (ona Tafura 2),309L welding zvinhuinofanira kufungwa nezvakawanda.Kana iwe uchida kuwana yakakwira Cr zvemukati, sarudza mhando312.

Chii chakakodzera pre-weld yekuchenesa oparesheni?

Paunenge uchipisa nezvimwe zvinhu, tanga wabvisa mafuta, mavanga uye guruva ne chlorine-isina solvent.Uye zvakare, chinhu chekutanga kutarisisa kana welding simbi isina tsvina ndeyekudzivisa kusvibiswa nekabhoni simbi uye kukanganisa kushomeka kwemarara.Mamwe makambani anochengeta simbi isina tsvina uye kabhoni simbi zvakasiyana kuti adzivise kusvibiswa.Shandisa yakakosha mavhiri ekukuya nemabhurashi esimbi isina tsvina paunenge uchichenesa nzvimbo yakatenderedza gorofu.Dzimwe nguva chibatanidza chinoda kucheneswa kechipiri.Nekuti iyo electrode muripo wekushanda kwestainless simbi welding yakanyanya kuoma kupfuura iyo yekabhoni simbi welding, kuchenesa kwakabatana kwakakosha zvikuru.

Nguva yekutumira: May-09-2023