Iyo welding electrode isimbi yesimbi inonyungudutswa uye inozadzwa pajoinhi rewelding work-piece panguva yekukweshesa gasi kana welding yemagetsi.Zvinhu zve electrode zvinowanzofanana nezvinhu zvebasa-chidimbu.

Pano isu tinosvika pakunzwisisa kuti sei neye welding electrode inoumbwa ne:

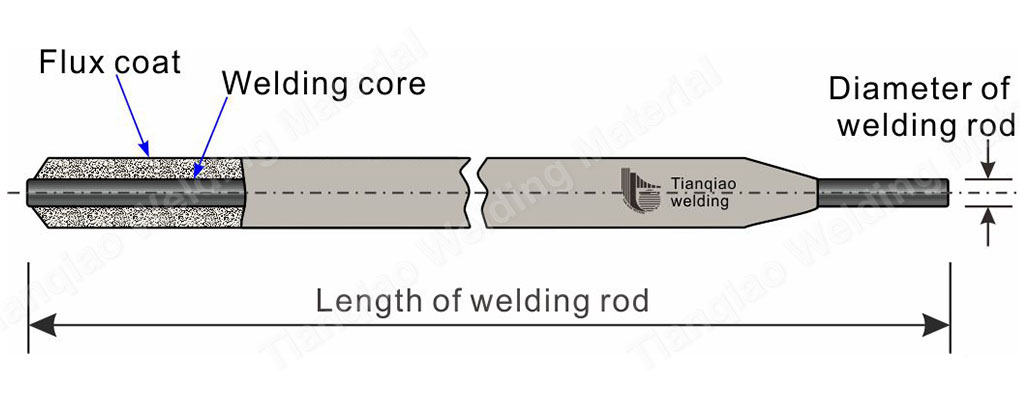

Mufananidzo 1 Chimiro cheTianqiao welding electrode

The welding electrode i electrode inonyunguduka yakavharidzirwa nejasi re arc welding ye welding tsvimbo.Inoumbwa nejasi uye welding core.

Nheyo yesimbi yakafukidzwa nekuputira mutsvimbo yewelding inonzi iyowelding core.Iyo welding core kazhinji iwaya yesimbi ine humwe hurefu uye dhayamita.

Mufananidzo 2 Core yeTianqiao welding electrode

Mabasa maviri epakati

1. Ita welding ikozvino uye gadzira arc kushandura simba remagetsi mukupisa.

2. Iyo welding core pachayo inonyunguduka sesimbi yekuzadza uye fuses neiyo liquid base simbi kuita weld.Kana welding ne electrode, iyo yepakati simbi inotora chikamu chese weld simbi.Naizvozvo, iyo kemikari yemhando ye weld core inokanganisa zvakananga kunaka kweiyo weld.Naizvozvo, waya yesimbi inoshandiswa seyepakati pe electrode ine mhando yayo uye kuumbwa kwakatsanangurwa zvakasiyana.

Electrode coatinginoreva rukuvhute rwakaiswa pamusoro peiyo welding core.Iyo yekuputira yakaora uye yakanyungudutswa mukuita welding kuti igadzire gasi uye slag, iyo inobata basa mukudzivirira kwemakanika, metallurgical kurapwa, uye kuvandudzwa kwemaitiro ekuita.

Mufananidzo 3 Kupfeka kweTianqiao welding electrode

Kuumbwa kwekuputira kunosanganisira: zvicherwa (zvakadai semarble, fluorspar, etc.), ferroalloys uye simbi poda (senge ferromanganese, ferro-titanium, nezvimwewo), zvinhu zvakasikwa (senge hupfu hwehuni, cellulose, nezvimwewo), zvigadzirwa zvemakemikari (senge titanium dioxide, girazi remvura, nezvimwewo).Electrode coating chinhu chakakosha pakuona kunaka kwewelds.

Mabasa makuru ekuputira mune welding process

1. Kuvandudza kugadzikana kwekupisa kwearc:

Iyo isina kuvharwa electrode haisi nyore kupisa arc.Kunyange ikatungidzwa, haigoni kupisa zvakadzikama.

2. Chengetedza dziva re weld:

Munguva yewelding process, okisijeni, nitrogen uye mhute yemvura mumhepo inopinda mukati meweld seam, iyo ichava nemhedzisiro yakaipa pamusono we weld.Kwete chete kuumbwa kwepores, asiwo kuderedza mechanical properties ye weld, uye kunyange kukonzera kuputika.Mushure mekunge electrode coating yakanyungudutswa, yakawanda gasi inogadzirwa yakavhara arc uye dziva rakanyungudutswa, izvo zvinoderedza kuwirirana pakati pesimbi yakanyungudutswa nemhepo.Kana iyo weld yakanyoroveswa, iyo yakanyunguduka yakanyunguduka inoumba dhizaini ye slag, iyo inovhara pamusoro peiyo weld, inodzivirira weld simbi uye inotonhorera zvishoma nezvishoma, ichideredza mukana weporosity.

Chetatu, kuve nechokwadi chekuti weld yave deoxidized uye desulfurized uye phosphorus tsvina

Kunyangwe dziviriro ichiitwa panguva yewelding process, zvichiri kusingadzivisike kuti shoma shoma yeokisijeni ichapinda mudziva rakanyungudutswa kuti iite oxidize simbi uye alloy zvinhu, kupisa zvinhu zvealloy, uye kuderedza kunaka kweweld.Nokudaro, zvakakosha kuwedzera mumiririri wekudzikisa (zvakadai semanganese, silicon, titanium, aluminium, nezvimwewo) kune electrode coating kuti kuderedze oxides akapinda mudziva rakanyungudutswa.

4. Wedzera alloying zvinhu zve weld:

Nekuda kwekupisa kwakanyanya kweiyo arc, iyo alloying zvinhu zve weld simbi ichave evaporated uye kupiswa, izvo zvinoderedza mechanical zvinhu zve weld.Naizvozvo, zvinodikanwa kuwedzera zvakakodzera alloying zvinhu kune weld kuburikidza nejasi kutsiva kupiswa kwekurasikirwa kwezvinhu zvealloy uye kuve nechokwadi kana kuvandudza ma mechanics eiyo weld.Pakuputira mamwe masimbi alloy, zvinodikanwa zvakare kupinza iyo alloy mu weld kuburikidza nekuputira, kuitira kuti weld simbi ive padhuze nekuumbwa kwesimbi ye base simbi, uye iyo mechanic properties inogona kubata kana kutopfuura. the base metal.

5. Kuvandudza kugadzirwa kwewelding uye kuderedza spatter:

Iyo electrode coating ine mhedzisiro yekuwedzera donhwe uye kuderedza spatter.Iyo yekunyungudika ye electrode coating yakaderera zvishoma pane welding point yepakati.Nekudaro, nekuti iyo welding core iri pakati pearc uye tembiricha yakakwira zvakanyanya, iyo welding core inonyungudika, uye yekubikira inonyungudika zvishoma gare gare.Panguva imwecheteyo, sezvo kurasikirwa kwesimbi kunokonzerwa ne spatter kwakaderedzwa, iyo deposition coefficient inowedzera, uye kugadzirwa kwewelding kunovandudzwa zvakare.

Nguva yekutumira: Jun-01-2021