Shielded Metal Arc Welding (yakapfupikiswa seSMAW).Nheyo yacho ndeyokuti: arc inogadzirwa pakati pe electrode yakavharidzirwa uye nheyo yesimbi, uye nzira yekugadzira inoshandisa kupisa kwearc kunyungudutsa electrode uye nheyo yesimbi.Iro kunze kwe electrode yakafukidzwa ne welding flux uye inonyunguduka kana yaiswa pakupisa, iyo ine mabasa ekudzikamisa arc, kugadzira slag, deoxidizing, uye kunatsa.Nekuti inoda midziyo iri nyore uye inochinjika kushanda, inogona kuve nyore welded kune welds inoumbwa nenzvimbo dzakasiyana uye majoini akasiyana munzvimbo.Naizvozvo, ichiri kushandiswa zvakanyanya iye zvino.

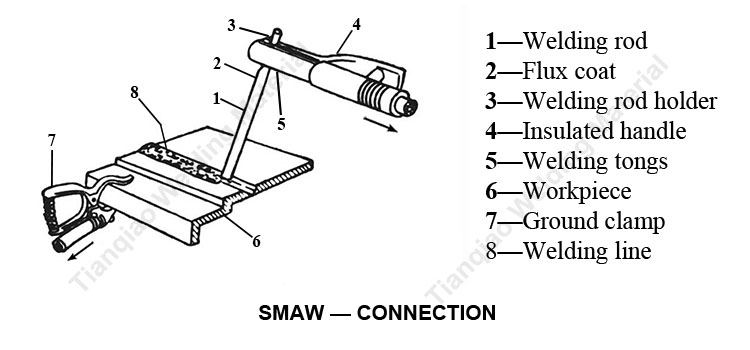

Mufananidzo 1: Shielded Metal Arc Welding-connection

Manual arc welding inoratidzwa mumufananidzo:

Usati waputira, batanidza welded workpiece uye welding tongs kumatanda maviri emagetsi emagetsi welding machine uye sunga tsvimbo yewelding nematonho emoto.Munguva yekuputika, tsvimbo yekutsvaira uye workpiece iri mukubatana pakarepo, ichiita dunhu diki, uye zvino inoparadzaniswa neimwe nzvimbo (inenge 2-4mm), uye arc inopiswa.

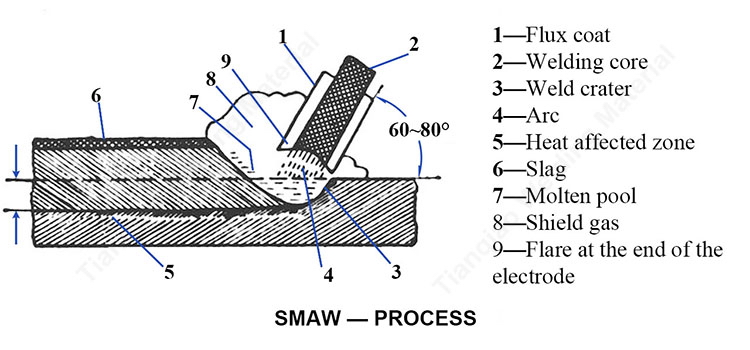

Mufananidzo 2: Shielded Metal Arc Welding-process

Iyo workpiece iri pasi pearc inobva yanyunguduka kuita semi-oval yakanyungudutswa dziva.Mushure mokunge electrode coating yakanyungudutswa, chikamu chayo chinova gasi rinopoteredza arc kuti riparadzanise kubva kumhepo, nokudaro kudzivirira simbi yemvura kubva kuokisijeni uye nitrogen;chikamu chacho chinobva chanyungudutswa, kana kupfapfaidzwa mudziva rakanyungudutswa chete, kana kunyungudutswa nepakati Madonhwe akanyunguduka esimbi yakanyunguduka anomwayiwa kudziva rakanyungudutswa pamwechete.

Muarc uye dziva rakanyungudutswa, iyo simbi yemvura, slag uye arc gasi ichaita dzimwe shanduko dzemuviri nemakemikari pamwe chete, sekunyungudika kwegasi musimbi yemvura uye oxidation-kuderedza kuita.Iyo gasi uye slag mudziva rakanyungudutswa zvinoyangarara kumusoro nekuda kwekureruka kwaro.Kana iyo arc yabviswa, tembiricha inodonha uye simbi uye slag zvichasimbisa imwe mushure meimwe.Nenzira iyi, zvidimbu zviviri zvesimbi zvinosanganiswa nesimbi yakanyungudutswa uye yakanatswa.Nemhaka yokuti shrinkage ye slag yakasiyana neiyo yesimbi, inotsvedza pane slag shell uye muganhu wesimbi, uye slag shell inogona kuwira pakarepo, kana kuwira pasi mushure mekugogodzwa, uye simbi weld seam ine zviyero zvehove. inogona kufumurwa.

Chishandiso chikuru chemanual arc welding ndeyemagetsi welding muchina.Magetsi welding muchina isimba remagetsi rinogadzira welding arc, uye kune marudzi maviri eAC neDC.Parizvino, kune akawanda marudzi emagetsi welding muchina anogadzirwa muChina, anogona kupatsanurwa kuita AC magetsi welding michina uye DC yemagetsi welding michina zvinoenderana nechimiro chavo.

Pane nzira mbiri dzakasiyana dzekubatanidza dzeDC welding michina.Kana iyo electrode yakabatanidzwa kune yakaipa electrode uye workpiece yakabatanidzwa kune yakanaka electrode, ndiyo nzira yakanaka yekubatanidza;zvakapesana ndiyo nzira yekubatanidza reverse.Kazhinji, kana welding nealkaline yakaderera-hydrogen electrode (sengeE7018, E7016), kuitira kuti arc apise zvakasimba, zvinotemerwa kushandisa iyo DC reverse yekubatanidza nzira;paunenge uchishandisa iyo acid electrode (sengeE6013, J422) kuti weld gobvu simbi mahwendefa, mberi yekubatanidza nzira inoshandiswa, nokuti anode chikamu Tembiricha yakakwirira kupfuura cathode chikamu, uye mberi yekubatanidza nzira inogona kuwana yakakura kupinda kudzika;kana welding simbi dzakatetepa mahwendefa uye asiri-ferrous simbi, reverse yekubatanidza nzira inoshandiswa.Kana welding nealternating current, sezvo polarity ichichinja neimwe nzira, hapana chikonzero chekusarudza polarity yekubatanidza.

Iyo welding material yemanual welding ndeye yemagetsi welding tsvimbo, iyo ine simbi core uye coating kunze kwesimbi core (OnawoKuumbwa kwewelding electrode).

Welding core

Basa resimbi yesimbi (welding core) inonyanya kuitisa magetsi uye kuumba simbi yakaiswa ine imwe kuumbwa pamagumo e electrode.Iyo welding core inogona kugadzirwa nesimbi dzakasiyana.Kuumbwa kweiyo welding core kunokanganisa zvakananga kuumbwa uye kuita kwesimbi yakaiswa.Naizvozvo, iyo welding core inodiwa kudzikisa zvirimo zvezvinokuvadza zvinhu.Pamusoro pekudzikamisa S uye P, mamwe matanda ewelding akuda iyo welding core kudzora As, Sb, Sn uye zvimwe zvinhu.

Mufananidzo 3: Tianqiao welding electrode E6013

Flux jasi

Electrode coating inogonawo kunzi pende.Chinangwa chikuru chekuipfekedza pamusimboti ndechekufambisa basa rewelding uye kuona kuti simbi yakaiswa ine imwe kuumbwa uye kuita.Electrode coatings inogona kusanganiswa nemazana ehupfu hwehupfu hwakaita seokisi, carbonates, silicates, organics, fluorides, ferroalloys uye zvigadzirwa zvemakemikari zvinoenderana neimwe formula reshiyo.Yakasiyana-siyana mbishi zvinhu zvinogona kukamurwa muzvikamu zvinotevera zvichienderana nebasa razvo mu electrode coating:

1. Stabilizer inoita kuti electrode ive nyore kutanga arc uye inogona kuchengetedza arc inopisa zvakasimba panguva yekugadzira.Chero chinhu chiri nyore kuita ionize chinogona kudzikamisa arc.Kazhinji, zvinosanganiswa zvealkali simbi uye alkaline pasi simbi, senge potassium carbonate, sodium carbonate, marble, nezvimwewo, inoshandiswa.

2. Slag-forming agent inogona kuumba slag yakanyungudutswa ine zvimwe zvemuviri uye zvemakemikari zvinhu panguva yekuputika, kuvhara pamusoro pesimbi yakanyungudutswa, kuchengetedza dziva rekutsvaira uye kuvandudza chimiro che weld.

3. Deoxidizer kuburikidza nemetallurgical chemical reaction muwelding process kuderedza okisijeni mukati me weld metal uye kunatsiridza mechanical properties ye weld.Iyo huru deoxidizers ndeye ferromanganese, ferrosilicon, uye ferro-titanium.

4. Gasi rinogadzira gasi rinogona kuparadzanisa uye kusunungura gasi pasi pekuita kwearc high tembiricha kudzivirira arc uye dziva rakanyungudutswa uye kudzivirira kupindira kweokisijeni uye nitrogen mumhepo yakapoteredza.

5. Alloying agent Inoshandiswa kubhadhara kupisa kwezvinhu zvealloy uye kuchinja kwezvinhu zvealloy kune weld panguva yekugadzira welding kuti ive nechokwadi chokuti weld metal inowana makemikari anodiwa uye kushanda.

6. Plasticizing Lubricant Wedzerai plasticity, kutsvedza uye fluidity yehupfu hwekuputira mu welding tsvimbo yekutsikirira nzira yekuvandudza kudzvanya kunaka kweiyo welding tsvimbo uye kuderedza eccentricity.

7. Adhesives Itai kuti poda yekuputira ive nehumwe viscosity panguva yekumanikidzika yekuputira, inogona kusungirirwa zvakasimba nechesi yewelding, uye ita kuti danda rekuputira rive nehumwe simba mushure mekuoma.

Nguva yekutumira: Jul-27-2021