Iko hakuna mutsauko mukuita pakati pe yakazara argon arc welding uye argon arc welding.Yakazara argon arc welding yakakodzera kune yakaonda-yakavezwa diki-diameter mapaipi (kazhinji DN60 uye pazasi, madziro ukobvu 4mm), chinangwa ndechekuona kunaka kweiyo weld midzi uye kutaridzika.

Kana iyo dhayamita yepombi yakakura uye ukobvu hwemadziro hwakakora, argon arc welding inofanira kushandiswa sehwaro uye nemaoko welding kuvhara pamusoro.Chinangwa chemanual welding ndechekuona kunaka kwekutaridzika kwepombi hombe dhayamita uye manual welding, uye kushanda zvakanaka kwakakwira kupfuura iyo argon arc welding.yakaderera pane argon arc welding.

Iyo argon arc welding bottom welding process inoshandiswa mukugadzira madziro eboiler water wall, superheaters, economizers, etc. Hunhu hwemajoini hwakanakisa, uye magiredhi eweld ari pamusoro peKirasi II mushure mekuongorora radiographic.

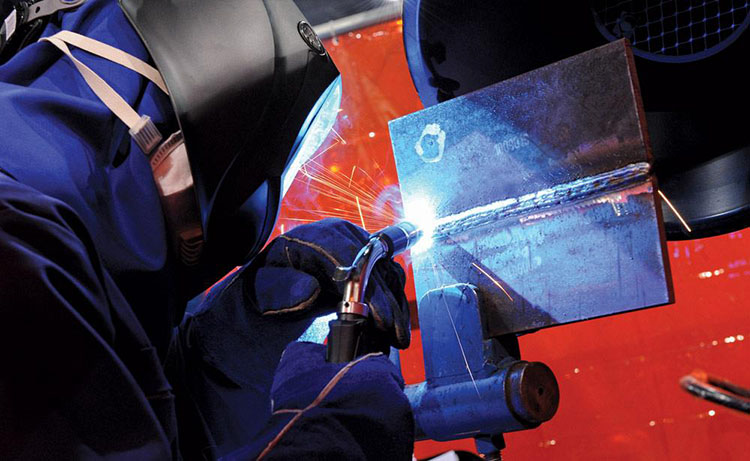

Zvakanakira argon arc welding

(1) unhu hwakanaka

Chero bedzi iyo yakakodzera welding wire, welding process parameters uye yakanaka gasi kudzivirira inosarudzwa, mudzi unogona kuwana kupindira kwakanaka, uye kupinza kwakafanana, uye pamusoro pacho pakanaka uye yakarongeka.Iko hakuna kukanganisa kwakadai seweld bumps, kupinda kusina kukwana, kuora mwoyo, pores uye slag inclusions zviri nyore kuitika panguva ye arc welding ne general electrodes.

(2) Kubudirira kwepamusoro

Muchikamu chekutanga chewelding yepombi, manual argon arc welding inoenderera mberi arc welding.Iyo electrode arc welding yakaputsika arc welding, saka manual argon arc welding inogona kuwedzera kugona nekaviri kusvika kane.Sezvo argon arc welding isingabudisi welding slag, hapana chikonzero chekuchenesa slag uye kugadzirisa weld bead, uye kukurumidza kunowedzera nokukurumidza.Muchikamu chechipiri chearc welding chivharo chepamusoro, iyo yakatsetseka uye yakarongeka argon welding yepasi layer inobatsira zvakanyanya kune arc welding yekuvharira pamusoro, iyo inogona kuve nechokwadi kusanganiswa kwakanaka pakati pematanho, kunyanya mukunyungudika kwepombi diki dhayamita, kushanda kwacho kunowedzera. zvakakosha.

(3) Zviri nyore kugona

Iyo welding yemudzi weld wemanual arc welding inofanirwa kuitwa nevane ruzivo uye vane hunyanzvi hwekuita.Manual argon arc welding inoshandiswa kutsigira, uye vashandi vanowanzoita basa rewelding vanogona kunyatsoriziva mushure menguva pfupi yekudzidzira.

(4) Deformation duku

Iyo inopisa-yakakanganiswa nzvimbo idiki zvakanyanya panguva yeargon arc welding, saka deformation yejoini yakashongedzwa idiki uye yakasara kushushikana zvakare idiki.

Kusuma nzira

(1) Welding muenzaniso

Iyo economizer, evaporator chubhu bundle, rusvingo rwemvura uye yakaderera-kupisa superheater inogadzirwa neNo.

(2) Kugadzirira usati welding

Usati waputirwa, muromo wepombi unofanirwa kuvharwa pamakumi matatu°, uye ruvara rwesimbi runofanira kukwenenzverwa mukati me15mm mukati nekunze kwepombi kupera.Mukaha pakati pemapombi epaipi ndeye 1 ~ 3mm.Kana iyo gap chaiyo yakakura kwazvo, zvinodikanwa kuti utarise shanduko yekuchinja padivi pepombi groove kutanga.Misa zvivakwa zvenguva pfupi zvekudzivirira mhepo uye unyatso kudzora kumhanya kwemhepo panzvimbo yekubatira welding, nekuti kumhanya kwemhepo kunodarika imwe nhanho, uye maburi emhepo anogadzirwa nyore.

(3) Kushanda

Shandisa manyorero tungsten argon arc welding muchina, welding muchina pachawo wakashongedzerwa ne-high-frequency arc ignition mudziyo, uye yakakwirira-frequency arc ignition inogona kushandiswa.Kudzima kweArc kwakasiyana neelectrode arc welding.Kana iyo arc ikadzimwa nekukasira, arc crater mitswe iri nyore kuitika.Naizvozvo, panguva yekushanda, dziva rakanyungudutswa rinofanirwa kuendeswa kumucheto kana kune gobvu simbi yesimbi, uye ipapo zvishoma nezvishoma inoderedza dziva rakanyungudutswa kudzima zvishoma nezvishoma arc, uye pakupedzisira kuvhara arc.Dziviriro gasi.

PaNo. 20 mapaipi esimbi ane madziro emadziro e3 ~ 4mm, iyo yekuzadza zvinhu inogona kuva TIGJ50 (ye12Cr1MoV, 08CrMoV inogona kushandiswa), iyo dhayamita yetungsten tsvimbo ndeye 2mm, iyo welding ikozvino 75 ~ 100A, iyo arc. voltage ndeye 12 ~ 14V, uye kuyerera kwemhepo yekudzivirira gasi ndeye 8 ~ 10L / min, rudzi rwemagetsi ndeye DC positive connection.

Chikonzero nei argon arc welding inogona kushandiswa zvakanyanya zvakanyanya nekuda kwezvinotevera zvakanakira.

1. Kudzivirirwa kweArgon kunogona kuparadzanisa migumisiro yakaipa yeokisijeni, nitrogen, hydrogen, nezvimwewo mumhepo pane arc uye dziva rakanyungudutswa, kuderedza kupisa kwekurasikirwa kwezvinhu zvealloy, uye kuwana dense, spatter-isina, yepamusoro-soro yakasungirirwa majoini;

2. Iyo arc kupisa kwe argon arc welding yakagadzikana, kupisa kwakadzika, iyo arc column tembiricha yakakwira, iyo welding yekugadzira inoshanda yakakwira, nzvimbo inobatwa nekupisa yakatetepa, uye kushushikana, deformation uye kutsemuka kweiyo welded. zvikamu zviduku;

3. Argon arc welding yakavhurika arc welding, iyo yakanakira kushanda uye kutarisa;

4. Kurasikirwa kwe electrode idiki, kureba kwearc kuri nyore kuchengetedza, uye hapana flux kana coating layer panguva yewelding, saka zviri nyore kuona mechanization uye otomatiki;

5. Argon arc welding inogona weld dzinenge simbi dzose, kunyanya dzimwe refractory simbi uye nyore oxidized simbi, akadai magnesium, titanium, molybdenum, zirconium, aruminiyamu, etc. uye alloys dzavo;

6. Haisi kuganhurirwa nechinzvimbo che weldment, uye inogona kusungirirwa munzvimbo dzose.

The main disvantages:

1. Pamusana penzvimbo yakakura inopisa ye argon arc welding, iyo workpiece inowanzokonzera deformation, kuoma kwakanyanya, blisters, annealing yemunharaunda, kuputika, pinholes, kupfeka, scratches, undercuts, kana kusakwana kwekubatanidza simba uye kushungurudzika kwemukati mushure mekugadzirisa.kuremara sekukuvara.Kunyanya mukugadzirisa zvikanganiso zviduku zvekutsvaga kwekutsvaga mari, inonyanya kuzivikanwa pamusoro.Mumunda wekugadzirisa kukanganisa kweiyo chaiyo castings, inotonhora welding michina inogona kushandiswa panzvimbo yeargon arc welding.Nekuda kwekupisa kudiki kuburitswa kweanotonhora welding michina, izvo zvinokanganisa zve argon arc welding zviri nani kukunda, uye matambudziko ekugadzirisa eiyo chaiyo castings anogadzirirwa.

2. Argon arc welding inokuvadza muviri wemunhu kupfuura electrode arc welding.Ikozvino density ye argon arc welding yakakwirira, uye chiedza chinobudiswa chakasimba.Iyo ultraviolet mwaranzi inogadzirwa nearc yayo ndeye yakajairika electrode arc welding.5 kusvika ku30 nguva, uye mwaranzi ye infrared inenge 1 kusvika 1.5 nguva ye electrode arc welding.Iyo ozone yemukati inogadzirwa panguva yewelding yakakwira zvakanyanya.Naizvozvo, edza kusarudza nzvimbo ine yakanaka kutenderera kwemhepo yekuvaka, kana zvisina kudaro ichakonzera kukuvadza kukuru kumuviri.

3. Kune simbi dzine yakaderera kunyungudika uye nyore evaporation (zvakadai somutobvu, tini, zingi), welding yakanyanya kuoma.

Nguva yekutumira: Aug-16-2023