Argon tungsten arc welding inoshandisa argon sechidziviriro gasi kupisa uye kunyungudutsa iyo welding iyo pachayo (inonyungudutswa zvakare kana simbi yekuzadza ichiwedzerwa) nenzira yearc inogadzirwa pakati pe tungsten electrode uye weld body, uye yobva yagadzira welding. ye weld metal Way.Thetungsten electrode,weld pool, arc uye joint seam nzvimbo inopisa nearc inodzivirirwa kubva pakusvibiswa kwemhepo nekuyerera kweargon.

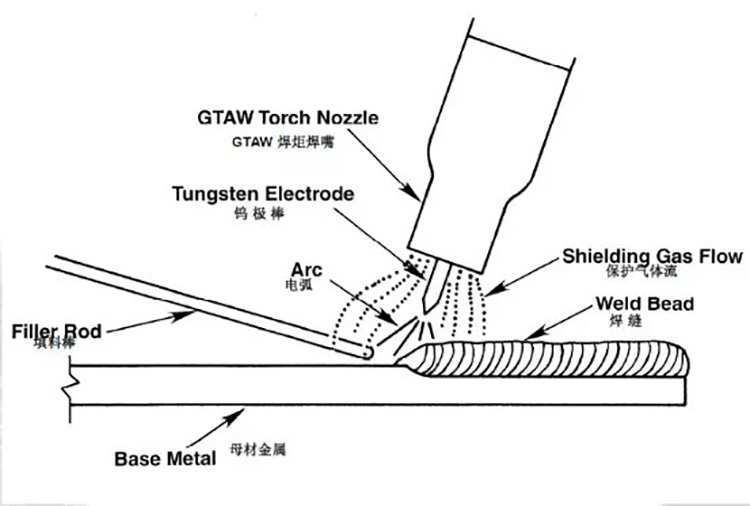

Munguva ye argon arc welding, nzvimbo dzinoenderana dzetochi, simbi yekuzadza uye weldment inoratidzwa mumufananidzo uri pazasi: kureba kwearc kunowanzo 1 ~ 1.5 times the diameter of the tungsten electrode.Kana iyo welding yakamira, simbi yekuzadza inotanga kubviswa kubva padziva rakanyungudutswa (simbi yekuzadza inowedzerwa zvichienderana nehupamhi hweiyo weldment), uye kupisa kunopisa kuchiri kufanira kugara pasi pekuchengetedzwa kwekuyerera kweargon kudzivirira oxidation yayo. .

1. Welding torch (torch)

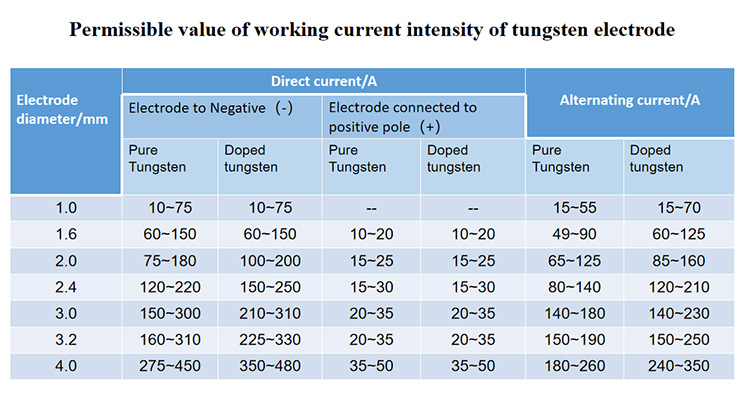

Pamusoro pekurovera tungsten electrode uye kuendesa welding ikozvino, iyo argon tungsten arc welding torch (inozivikanwawo setochi rewelding) inodawo kupfapfaidza gasi rinodzivirira.High-current welding pfuti dzinoda kushandisa mvura-yakatonhodzwa welding pfuti dzenguva refu.Nokudaro, kushandiswa kwakarurama uye kudzivirirwa kwetochi yewelding kwakakosha zvikuru.Tungsten electrode mutoro ikozvino simba (A) inoratidzwa mutafura pazasi.

2. Gasi nzira

Iyo gasi nzira inoumbwa neargon cylinder pressure yekudzikisa valve, kuyerera mita, hose uye electromagnetic gasi vharafu (mukati mewelding muchina).Ivhavha inoderedza simba inoshandiswa kuderedza kudzvinyirira uye kugadzirisa kudzvinyirira kwegasi rinodzivirira.Iyo flowmeter inoshandiswa kugadzirisa uye kugadzirisa inodzivirira gasi kuyerera.Argon arc welding michina inowanzo shandisa yakasanganiswa decompression flowmeter, iri nyore uye yakavimbika kushandisa.

Munguva yeArgon arc welding, chinodiwa chekuchena kweargon gasi ndechekuti chromium-nickel simbi isina tsvina inofanira kuva ≥99.7%, uye refractory simbi inofanira kuva ≥99.98%.

(1) Argon igasi inert, uye hazvisi nyore kuita nezvimwe zvinhu zvesimbi nemagasi.Uyezve, nekuda kwekutonhora kwekuyerera kwemhepo, iyo inopisa-yakakanganiswa nzvimbo ye weld idiki uye deformation ye weldment idiki.Ndiyo yakanyanya kunaka kudzivirira gasi kune argon tungsten arc welding.

(2) Argon inonyanya kushandiswa kuchengetedza dziva rakanyungudutswa zvinobudirira, kudzivirira mhepo kubva pakubvisa dziva rakanyungudutswa uye kukonzera oxidation panguva yekugadzira, uye panguva imwe chete inonyatso kuparadzanisa mhepo munzvimbo yeweld, kuitira kuti nzvimbo yeweld iite. yakadzivirirwa uye iyo welding performance inovandudzwa.

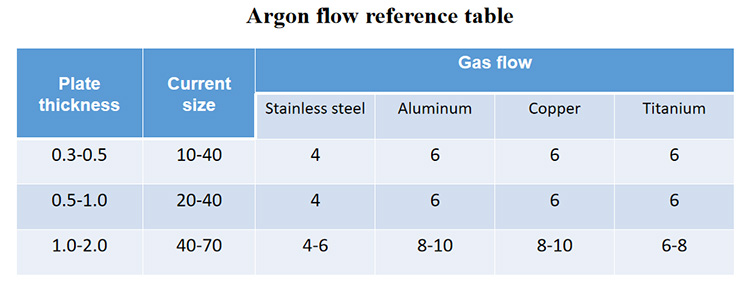

(3) Nzira yekugadzirisa inotarirwa maererano nesimbi inosungirirwa, ukuru hwemazuva ano, uye nzira yekugadzira: iyo yakakura ikozvino, iyo yakawanda yekudzivirira gasi.Kune inoshanda zvinhu zvekushandisa, gasi rinodzivirira rinofanira kusimbiswa kuti riwedzere kuyerera.

3. Tsanangudzo parameters

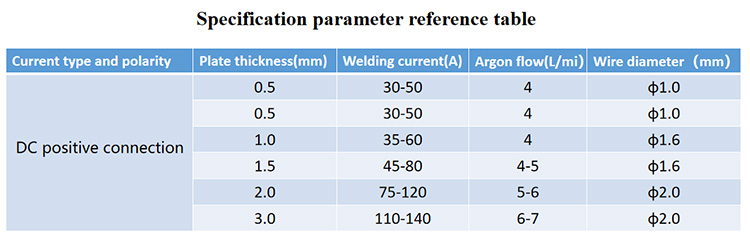

Iwo akajairwa paramita eargon tungsten arc welding anonyanya kusanganisira ikozvino, voltage, welding kumhanya, uye argon gasi kuyerera, uye hunhu hwazvo hune hukama nerudzi rwezvinhu zvinosungirwa, ukobvu hweplate uye rudzi rwekubatana.

Maparamendi asara akadai sehurefu hwetungsten electrode inobuda kubva pamuromo kazhinji ka1-2 pahupamhi hwetungsten electrode, chinhambwe chiri pakati petungsten electrode uye weldment (arc kureba) kazhinji kakapetwa ka1.5 kudhayamita kwetungsten. electrode, uye saizi yemhino inotarwa mushure mekunge kukosha kwazvino welding kwatemwa.Sarudza zvakare.

General Stainless simbi argon arc welding maratidziro ndeaya anotevera:

4. Kucheneswa tisati tasveta

Tungsten argon arc welding inotarisisa zvakanyanya kusvibiswa kweiyo weldment uye filler simbi pamusoro, saka girisi, kupfekedza, lubricant uye oxide firimu pamusoro peiyo weldment inofanira kubviswa isati yaiswa.

5. Tekinoroji yekuchengetedza

Vashandi ve argon tungsten arc welding vanofanira kupfeka masiki emusoro, magurovhosi, mbatya dzebasa, uye shangu dzebasa kudzivirira ultraviolet uye infrared kutsva muarc.Steyr tungsten argon arc welding michina ine yakakwira-frequency arc kutanga.Kunyangwe iyo yakaderera-simba yakakwira-frequency yakakwira-voltage magetsi haizovhundutsi mushandisi, kana iyo insulation performance isina kunaka, iyo yakakwira-frequency magetsi ichapisa ganda reruoko rweanoshanda, uye zvakaoma kurapa, saka iyo insulation performance. ye welding handle inofanira kuongororwa nguva nenguva.Munguva yeArgon tungsten arc welding, kufefetedza munzvimbo yewelding kunofanirwa kuvandudzwa.

Cherechedza: Chinhu chikuru ndechekuve nehunyanzvi uye dexterous.Ukobvu hwebhodhi, nguva yekudzvanya, uye ikozvino zvese zvine hukama, uye zvinofanirwa kushandira pamwe.

Paunenge uchitsvaira, usanongedza tsono panzvimbo yewelding pakutanga, uye urove isina chinhu kutanga kuti ubudise mhepo mupombi, kuitira kuti welding irege kuputika uye hapazovi nemavara matema.Masekonzi mashomanana, nenzira iyi, simbi isina tsvina inodzivirirwa ne argon gasi panguva yekutonhora, saka haizove yakasviba, uye kunyange mvura yekugeza uye pepa rekupukuta zvinoponeswa.Izvi zvinogona kushandiswa chete kune nzvimbo welding.Kana iwe ukadhonza welding kwechinhambwe chakareba, hapana nzira.Bhodhi ichanyatso shandura ruvara.Iwe unofanirwa kumirira kukwenenzverwa uye kuchenesa.

Nguva yekutumira: May-16-2023