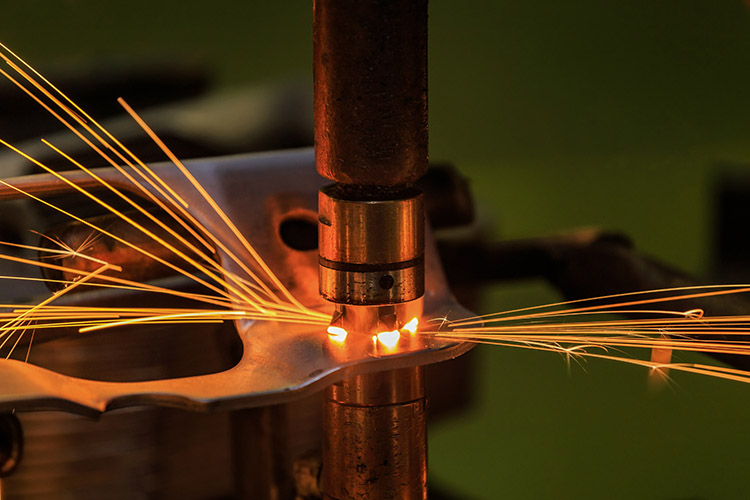

Spot welding is a resistance welding method umo iyo weldment inounganidzwa kuita lap joint uye yakatsikirirwa pakati pemaelectrodes maviri, uye base simbi inonyungudutswa nekupikiswa kupisa kuti iite solder joint.

Spot welding inonyanya kushandiswa mune zvinotevera zvinhu:

1. Pep joint yemashizha ekutsika, senge mota cab, ngoro, hove scale screen yekukohwa, nezvimwe.

2. Ndiro yakatetepa uye zvikamu zvesimbi zvimiro uye zvimiro zveganda, senge madziro emadziro uye sirin'i yezvingoro, trailer compartment panels, batanidza makona funnels, nezvimwe.

3. Masikirini, mafuremu emuchadenga nemazariro, nezvimwe.

Characteristic

Munguva yewelding, iyo weldment inogadzira lap joint uye inotsikirirwa pakati pema electrode maviri.Hunhu hwayo hukuru ndeiyi:

1. Nguva yekupisa yenzvimbo yekubatanidza ipfupi kwazvo panguva yekucheka kwemavara, uye kukurumidza kwewelding kunokurumidza.

2. Spot welding inongopedza simba remagetsi, uye haidi kuzadza zvinhu kana flux, gasi, nezvimwe.

3. Hunhu hwenzvimbo welding hunonyanya kuvimbiswa neapo welding muchina.Iko kushanda kuri nyore, dhigirii remakanika uye otomatiki rakakwira, uye kugadzirwa kwacho kwakakwira.

4. Kuderera kwebasa rakaoma uye mamiriro akanaka ekushanda.

5. Sezvo welding energization inopedzwa munguva pfupi, yakakura ikozvino uye kumanikidzwa kunodiwa, saka chirongwa chekutonga kwechirongwa chacho chakanyanya kuoma, welding machine ine simba guru, uye mutengo wezvigadzirwa zvishoma. high.

6.Zvakaoma kuitisa kuongororwa kusingakuvadzi pamajoini e solder.

Operation process

Pamusoro pe workpiece inofanira kucheneswa isati yaputira.Iyo inowanzoshandiswa yekuchenesa nzira ndeye pickling yekuchenesa, kureva, kunhonga mumhepo inopisa sulfuric acid ine musanganiswa we10%, uye wozogeza mumvura inopisa.Iyo chaiyo welding process ndeiyi inotevera:

(1) Tumira iyo workpiece yakabatana pakati pepamusoro nepasi maelectrode eiyo nzvimbo welding muchina uye woisunga;

(2) electrification, kuitira kuti nzvimbo dzekubatana dzezvishandiso zviviri zvidziye uye zvinyunguduke zvishoma kuti zvigadzire nugget;

(3) Chengetedza kudzvinyirira mushure mokunge simba ragurwa, kuitira kuti nugget itonhodzwe uye isimbiswe pasi pekumanikidzwa kuti iite solder joint;

(4) Bvisa kumanikidzwa uye tora workpiece.

Kufurira zvinhu

Zvinhu zvikuru zvinokanganisa welding mhando ndeye welding ikozvino uye simba nguva, electrode pressure uye shunt, nezvimwe.

1. Welding ikozvino uye simba nguva

Zvinoenderana nehukuru hweiyo welding ikozvino uye nehurefu hwenguva yekusimbisa, nzvimbo welding inogona kupatsanurwa mumhando mbiri: yakaoma kududzira uye yakapfava.Tsanangudzo inopfuura yakakura ikozvino munguva pfupi inonzi yakaoma tsanangudzo.Iyo ine mabhenefiti ekugadzirwa kwepamusoro, hupenyu hurefu hwe electrode, uye diki deformation ye weldment.Inokodzera simbi yewelding ine zvirinani thermal conductivity.Tsanangudzo inopfuura diki ikozvino kwenguva yakareba inodaidzwa kuti yakapfava, iyo ine chibereko chakaderera uye inokodzera simbi dzinopisa dzinowanzo kuoma.

2. Electrode pressure

Panguva yekugadzira nzvimbo, kudzvinyirirwa kunoitwa ne electrode pane weldment kunonzi electrode pressure.Iyo electrode pressure inofanira kusarudzwa zvakakodzera.Kana dzvinyiriro yakakwira, iyo shrinkage porosity uye shrinkage cavity inogona kuitika kana nugget ichisimba inogona kubviswa, asi kupikisa kwekubatanidza uye density yemazuva ano inodzikira, zvichikonzera kusakwana kwekupisa kweiyo weldment uye kuderera kwedhayamita ye nugget ye. solder joint.Simba rejoint solder rakaderedzwa.Saizi ye electrode pressure inogona kusarudzwa zvichienderana neizvi zvinotevera zvinhu:

(1) Zvigadzirwa zveweldment.Iyo yakakwirira yekushisa kwepamusoro simba rezvinhu.Iyo yakakura iyo electrode pressure inodiwa.Naizvozvo, kana uchitungidza simbi isina simbi nesimbi isingadziviriri kupisa, kudzvanywa kwe electrode kunofanirwa kunge kuri pamusoro peiyo yepasi kabhoni simbi.

(2) Welding parameters.Iyo yakanyanya kuoma iyo weld yakatarwa, iyo yakakura iyo electrode pressure.

3. shunt

Munguva yekugadzira nzvimbo, ikozvino inoyerera ichibva kunze kwewelding main circuit inonzi shunt.Iyo shunt inoderedza ikozvino inoyerera kuburikidza nenzvimbo yewelding, zvichikonzera kusakwana kwekudziya, zvichikonzera kuderera kukuru kwesimba rejointi rekutengesa uye kukanganisa kunaka kwewelding.Izvo zvinhu zvinokanganisa dhigirii rekutsauka zvinonyanya zvinosanganisira zvinotevera zvinhu:

(1) Ukobvu hweweldment uye kuparadzaniswa kwemajoini emasoja.Sezvo kureba pakati pemajoini ekutengesa kunowedzera, shunt kuramba inowedzera uye dhigirii reshunt rinoderera.Kana iyo yakajairwa dot pitch ye30-50mm inogamuchirwa, iyo shunt ikozvino inoverengera 25% -40% yezvese ikozvino, uye nekukora kweiyo weldment inoderera, dhigirii reshunt rinodererawo.

(2) Mamiriro ekunze eiyo weldment.Kana paine maokisi kana tsvina pamusoro peiyo weldment, kusangana kwekupokana pakati pemaviri weldment kunowedzera, uye ikozvino kuburikidza nenzvimbo yewelding inoderera, ndiko kuti, dhigirii reshunt rinowedzera.Iyo workpiece inogona kuve yakabikwa, sandblasted kana kupushwa.

Chengetedzo Yekuchengetedza

(1) Chitsiko chetsoka chemuchina welding chinofanira kunge chine chivharo chakasimba chekudzivirira kudzivirira kuita netsaona.

(2) Nzvimbo yekushanda ichave yakashongedzerwa nebaffle kudzivirira kupfachuka kwemapfunde ekushanda.

3

(4) Nzvimbo inoiswa muchina we welding inofanira kugara yakaoma, uye pasi panofanira kuvharwa ne anti-skid board.

(5) Mushure mebasa rekushongedza, magetsi anofanirwa kubviswa, uye shanduko yemvura inotonhorera inofanira kuwedzerwa kwemasekonzi gumi isati yavhara.Kana tembiricha yadzikira, mvura yakaunganidzwa mumvura inofanira kubviswa kudzivirira kutonhora.

Nguva yekutumira: Jul-31-2023