Iyo yekuputira inotamba yakaoma metallurgical reaction uye yemuviri uye kemikari shanduko muwelding process, iyo inonyanya kukurira matambudziko muwelding yephoto electrode, saka kupfekedza zvakare chimwe chezvinhu zvakakosha kuona kunaka kwesimbi weld.

Electrode coating:Inoreva iyo yekuputira layer yeakanaka granular zvinhu zvine akasiyana emuviri uye makemikari zvimiro zvakafanana zvakavharwa pamusoro peiyo welding core.

Basa rewelding electrodeCoating:Mukuita welding, inoumba slag ine yakakodzera kunyungudika nzvimbo, viscosity, density, alkalinity uye zvimwe zvemuviri uye kemikari zvivakwa, kuve nechokwadi chekugadzika kwearc kupisa, kuita kuti droplet simbi ishanduke nyore, inogadzira mamiriro akatenderedza arc zone uye dziva rakanyungudutswa kudzivirira. iyo welding nzvimbo, uye uwane yakanaka weld kuumbwa uye kuita.Nekuwedzera deoxidizer, alloying element kana zvimwe zviri mukati meiron poda pakuputira, inogona zvakare kusangana nezvinodiwa zve weld metal performance kana kuvandudza kunyungudika.

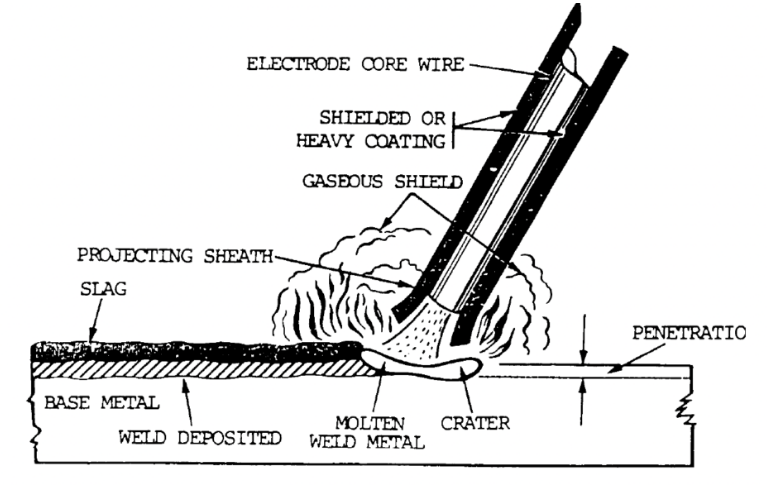

Nheyo ye electrode arc welding:

1. Mushonga ganda

2. Weld core

3. Chengetedza gasi

4: Arc

5. Dziva rakanyungudutswa

6. Base zvinhu

7. Weld

8. Welding slag

9. Slag

10. Nyusa madonhwe

Yakasiyana-siyana mbishi zvinhu zvinoenderana nebasa ravo mu electrode coating inogona kukamurwa kuita:

(1) Arc stabilizer

Basa guru nderekuita kuti electrode ive nyore kutanga arc uye kuchengetedza arc yakagadzikana kupisa mukupisa.Sezvo arc stabilizer mbishi zvinhu zvakanyanya zvimwe zvine imwe nhamba yakaderera ionization inogona nyore ionizing zvinhu, senge feldspar, sodium silicate, rutile, titanium dioxide, marble, mica, ilmenite, yakaderedzwa ilmenite zvichingodaro.

(2) Gasi kugadzira agent

Pasi pechiito chepamusoro tembiricha arc decomposition gasi, kugadzira mhepo inodzivirira, chengetedza arc uye simbi yakanyungudutswa, kudzivirira kupindira kweokisijeni uye nitrogen mumhepo yakapoteredza.Gasi rinoshandiswa rinowanzoshandiswa ndiro carbonate (yakadai semarble, dolomite, rhombic acid, barium carbonate, nezvimwewo) uye organic matter (sehuni hupfu, starch, cellulose, resin, nezvimwewo).

(3) Deoxidizer (inozivikanwawo seanoderedza mumiririri)

Iyo okisijeni yemukati mune weld simbi inogona kudzikiswa uye kuita kwe weld simbi inogona kuvandudzwa nekemikari metallurgical reaction muwelding process.Deoxidizer inonyanya kuve nezvinhu zvesimbi alloy uye simbi poda ine hukama hukuru hweokisijeni.Inowanzo shandiswa deoxidizer ndeye ferromanganese, ferrosilicon, ferrotitanium, ferroaluminum, silicon calcium alloy, nezvimwe.

(4) Plasticizer

Basa rayo guru nderokuvandudza plastiki, elasticity uye fluidity mukugadzirisa electrode iri kudzvinyirirwa coating , kuvandudza kunaka kwekuputira kwe electrode, kuitira kuti nzvimbo yakatsetseka ye electrode coating haina kuputika.Kazhinji sarudza imwe elasticity, inotsvedza kana kunyura mushure meimwe yekuwedzera maitiro emidziyo, senge mica, chena dope, titanium dioxide, talc, girazi remvura yakasimba, cellulose, nezvimwe.

(5) Alloy agent

Inoshandiswa kutsiva kupisa kwealloying zvinhu muwelding process uye kuendesa alloying zvinhu kune weld, kuitira kuti ive nechokwadi chekuumbwa kwemakemikari uye zvimiro zveweld simbi.Zvinoenderana nezvinodiwa zvekusarudza zvakasiyana-siyana zveferroalloys (senge ferromanganese, ferrosilicon, ferrochrome, iron uye simbi, ferric vanadium, ferric niobium, ferric boron, isingawanzo pasi ferrosilicon, nezvimwewo) kana simbi yakachena (senge manganese simbi, chromium simbi , nickel poda, tungsten hupfu, nezvimwewo).

(6) Slag kugadzira agent

Welding inogona kuumba imwe yemuviri uye kemikari zvimiro zveyakanyungudutswa slag, chengetedza iyo welding droplet uye yakanyungudutswa dziva simbi, kunatsiridza weld kuumbwa, senge slagging mumiririri wezvakagadzirwa mabhura, fluorite, dolomite, magnesia, feldspar, chena dope, mica, quartz. , rutile, titanium dioxide, ilmenite, nezvimwe.

(7) Binder

Iyo yekuvhara zvinhu yakanyatsobatanidzwa kune welding core, uye iyo electrode coating ine rimwe simba mushure mekuoma.Mukuita welding metallurgy, hapana chinokuvadza pane weld pool uye weld simbi.Anowanzo shandiswa mabhanhire ndeye sodium silicate (potassium, sodium uye yakasanganiswa sodium silicate) uye phenolic resin, chingamu, nezvimwe.

Nguva yekutumira: May-04-2023