-FLUX-

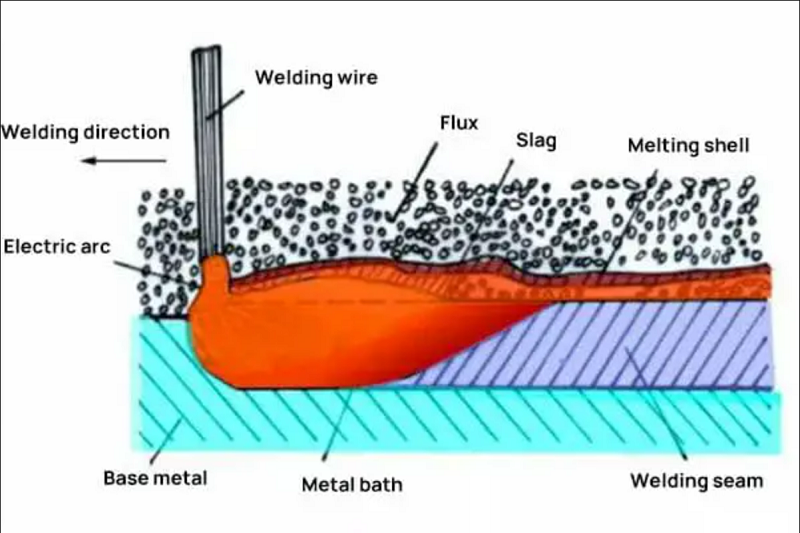

Fluxis a granular welding material.Panguva yekuputika, inogona kunyungudutswa kuita slag uye gasi, iyo inotamba basa rekudzivirira uye resimbi padziva rakanyungudutswa.

Constituent

Flux inoumbwa nemarble, quartz, fluorite uye mamwe ores uye titanium dioxide, cellulose nemamwe makemikari.Flux inonyanya kushandiswa kune yakanyura arc welding uye electroslag welding.Kana yakashandiswa kunyorera marudzi ese esimbi uye asiri ferrous simbi, inofanira kuva inonzwisisika kushandiswa neino enderana welding waya kuitira kuti uwane inogutsa weld.

Classification

Kune akawanda emhando nzira dzekuyerera, zvinoenderana nekushandiswa, nzira yekugadzira, makemikari kuumbwa, welding uye metallurgical zvimiro zvechikamu, asi zvakare zvinoenderana neiyo pH yekuyerera, flux granularity classification.Hazvina mhosva kuti ndeupi rudzi rwenzira yekuisa, inongoratidza hunhu hwekuyerera kubva pane chimwe chinhu, haigone kusanganisira ese maitiro ekuyerera.Nzira dzinonyanya kushandiswa dze classification ndeidzi:

1. Neutral flux

Neutral flux inoreva kuyerera kusinganyanyi kushandura kemikari yesimbi yakasanganiswa uye kemikari yewaya yewelding mushure mekugadzira.Neutral flux inoshandiswa kune akawanda-pass welding, kunyanya kukwenenzverwa kwesimbi yepasi ine ukobvu hunodarika 25mm. Neutral flux ine zvinotevera maitiro:

a.Iyo inoyerera haina chaizvo SiO2, MnO, FeO uye mamwe maokisi.

b.Flux haina oxidation mhedzisiro pane weld simbi zvakanyanya.

c.Kana welding base simbi ine yakanyanya oxidation, pores uye weld makatsemuka anogadzirwa.

2. Active flux

Active flux inoreva kuwedzera kwehuwandu hushoma hweMn, Si deoxidizer flux.Inogona kuvandudza kuramba kune porosity uye kuputika.Active flux ine zvinotevera maitiro:

a.Nekuda kwe deoxidizer, Mn naSi musimbi yakanyungudutswa inoshanduka nearc voltage.Kuwedzera kweMn naSi kuchawedzera simba resimbi yakanyungudutswa uye kuderedza kuoma kwesimba.Naizvozvo, arc voltage inofanirwa kudzorwa zvakanyanya kana akawanda - pass welding.

b.Active flux ine yakasimba porosity resistance.

3. Alloy flux

Alloy flux yakawedzera zvimwe alloy zvikamu zveshanduko yealloying zvinhu, mazhinji eiyo alloying flux is sintered flux.Alloy flux inonyanya kushandiswa kugadzira yakaderera alloy simbi uye kupfeka-inodzivirira pamusoro pepamusoro.

4. Melt flux

Melt flux ndiyo mbishi yezvicherwa zvakasiyana-siyana zvakakanyiwa zvinoenderana nechiyero chakapihwa, chinopisa kusvika kune anopfuura 1300 madhigirii, yakanyungudutswa uye nekukandwa zvakaenzana, yozotonhodzwa mumvura kuita granulate.Mushure mekuoma, kukuya, kuongorora, kurongedza kushandiswa.

Iyo mhando yekunyungudika kwemukati memba inoratidzwa ne "HJ".Dhijiti yekutanga mushure meiyo inoratidza zviri mukati meMnO, yechipiri digit inoratidza zvirimo zveSiO2 neCaF2, uye yechitatu digit inoratidza mhando dzakasiyana dzemhando imwechete yekuyerera.

5. Sintering flux

Iyo yakaoma yakasanganiswa maererano nechikamu chakapihwa chezvishandiso, uye wobva wawedzera binder (girazi remvura) yekunyorova kusanganisa, uye ipapo granulation, uye wozotumirwa kune yekuomesa choto kurapa, kuomesa, uye pakupedzisira sintered neanenge 500 madhigirii.

Chiratidzo chepamba sintered flux inomiririrwa ne "SJ", yekutanga digit mushure meiyo inomiririra slag system, uye yechipiri neyechitatu manhamba inomiririra mhando dzakasiyana dzeiyo yakafanana slag system flux.

Nguva yekutumira: May-04-2023