The welding residual stress inokonzerwa nekusaenzana tembiricha kugoverwa kweweldment kunokonzerwa newelding, thermal expansion and contraction of the weld metal, etc., saka kuvakwa kwewelding kunozoburitsa zvakasara stress.

Nzira yakajairika yekubvisa kushushikana kwakasara ndeyekupisa-kupisa, ndiko kuti, kupisa iyo weldment kune imwe tembiricha uye kuibata kweimwe nguva yenguva muchoto chekurapa kupisa, uye kushandisa kuderedzwa kwegoho muganhu wezvinhu. pakupisa kwepamusoro kukonzera kuyerera kwepurasitiki munzvimbo dzine kushushikana kwakanyanya kwemukati.Iyo elastic deformation inodzikira zvishoma nezvishoma, uye deformation yepurasitiki inowedzera zvishoma nezvishoma kuderedza kushushikana.

1.Kusarudzwa kwekupisa nzira yekurapa

Mhedzisiro ye-post-weld kupisa kurapwa pane simba rekusimba uye inokambaira muganho wesimbi inoenderana nekupisa kwekupisa tembiricha uye kubata nguva.Mhedzisiro ye-post-weld kupisa kurapwa pane kukanganisa kuoma kwesimbi weld inosiyana nemhando dzakasiyana dzesimbi.

Post-weld kupisa kurapwa kazhinji kunotora imwe yakakwirira-tembiricha kudzikama kana normalizing pamwe nepamusoro-tembiricha tembiricha.Kune gasi welding majoini, normalizing uye yakakwirira tembiricha tembiricha inogamuchirwa.Izvi zvinodaro nekuti zviyo zvegasi welding seam uye iyo inopisa-yakakanganiswa nzvimbo yakaoma, uye zviyo zvinoda kunatswa, saka kurapa kwakajairika kunogamuchirwa.

Nekudaro, imwechete normalizing haigone kubvisa kushushikana kwasara, saka tembiricha yakanyanya inodiwa kubvisa kushushikana.Iyo imwe yepakati-tembiricha tembiricha inokodzera chete kuungana uye welding yezvakajairwa zvakaderera-kabhoni simbi midziyo yakaunganidzwa panzvimbo, uye chinangwa chayo ndechekuzadzisa chikamu chekubvisa kusara kwekushushikana uye dehydrogenation.

Muzviitiko zvakawanda, imwe chete yakakwirira tembiricha tempering inoshandiswa.Kupisa uye kutonhora kwekupisa kwekupisa hakufaniri kunge kwakakurumidza, uye masvingo emukati nekunze anofanira kunge akafanana.

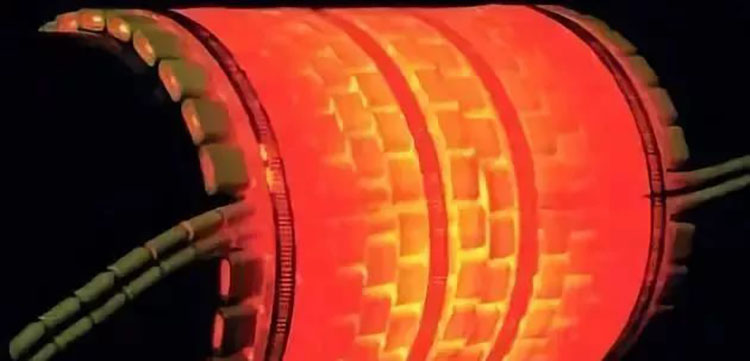

2.Kupisa nzira dzekurapa dzinoshandiswa mumidziyo yekumanikidza

Kune marudzi maviri emhando dzekupisa nzira dzekumanikidza midziyo: imwe yekupisa kurapwa kuvandudza mechanical properties;imwe yacho ndeye post-weld heat treatment (PWHT).Kunyatsotaura, post-weld kupisa kurapwa ndiko kupisa kwenzvimbo yakashongedzwa kana welded components mushure mekunge workpiece yaiswa welded.

Izvo chaizvo zvemukati zvinosanganisira kudzoreredza kushushikana, kuvharisa kwakazara, yakasimba mhinduro, normalizing, normalizing pamwe nekudzikamisa, kudzikisira, kudzikira tembiricha kusagadzikana, kunaya kwemvura kurapwa, nezvimwe.

Nenzira yakamanikana, post-weld kupisa kurapwa kunongoreva kumisa kushushikana kudzikamisa, ndiko kuti, kuitira kuvandudza mashandiro enzvimbo yewelding uye kubvisa zvinokuvadza zvakaita senge welding yakasara kushushikana, kuitira kuti ifanane uye izere kupisa iyo welding zone. uye zvikamu zvine hukama pazasi pesimbi chikamu shanduko 2 tembiricha poindi, uyezve maitiro ekutonhodza yunifomu.Muzviitiko zvakawanda iyo postweld kupisa kurapwa inokurukurwa yanyanya postweld kushushikana kunyaradza kupisa kurapwa.

3.Chinangwa che post weld kupisa kurapwa

(1).Relax welding residual stress.

(2).Gadzirisa chimiro uye hukuru hwechimiro uye kuderedza kukanganisa.

(3).Kuvandudza kushanda kwesimbi yekutanga uye majoini akaiswa, kusanganisira:

a.Kuvandudza plastiki ye weld metal.

b.Deredza kuoma kwenzvimbo inopisa-inopisa.

c.Kuvandudza fracture kuoma.

d.Kuvandudza simba rekuneta.

e.Dzorera kana kuwedzera simba regoho rakaderedzwa mukutonhora kuumba.

(4).Vandudza kugona kurwisa kusagadzikana ngura.

(5).Kuwedzera kuburitsa magasi anokuvadza musimbi ye weld, kunyanya hydrogen, kudzivirira kuitika kwekunonoka kutsemuka.

4.Kutonga kwekudikanwa kwePWHT

Kunyangwe iyo post-weld kupisa kurapwa kwakakosha kune yekumanikidza mudziyo inofanira kutsanangurwa zvakajeka mukugadzira, iyo inodiwa neyazvino yekumanikidza mudziyo dhizaini kodhi.

Kune welded pressure midziyo, kune yakakura yakasara kushushikana munzvimbo yewelding, uye yakashata mhedzisiro yekusarira kunetseka.Zvinongoratidzwa mune mamwe mamiriro.Kana iyo yakasara kushushikana inosanganiswa ne hydrogen mu weld, inosimudzira kuomarara kwenzvimbo inobatwa nekupisa, zvichikonzera chizvarwa chekutsemuka kwechando uye kunonoka kutsemuka.

Kana iyo static stress yasara mu weld kana simba remutoro kushushikana mukushanda kwemutoro inosanganiswa neiyo corrosion action yepakati, inogona kukonzera crack corrosion, inova iyo inonzi stress corrosion.Welding residual stress uye base simbi kuomarara kunokonzerwa newelding zvinhu zvakakosha zvekunetsekana nekukoromoka kutsemuka.

Mhedzisiro yetsvagiridzo inoratidza kuti mhedzisiro huru yekukanganisa uye kusara kunetseka pazvinhu zvesimbi kuita kuti simbi ichinje kubva mukuora yunifomu kuenda kucorrosion yemunharaunda, kureva, kune intergranular kana transgranular corrosion.Ehe, zvese corrosion cracking uye intergranular corrosion yesimbi inoitika munhau dzine humwe hunhu hwesimbi iyoyo.

Muhupo hwekusarira kushushikana, zvakasiyana zvichienderana nekuumbwa, kusungirirwa uye tembiricha yepakati inoparadza, pamwe nekusiyana kwekuumbwa, chimiro, chimiro chepasi, mamiriro ekushushikana, nezvimwe zve base simbi uye welding zone. , kuitira kuti ngura Chimiro chekukuvara chinogona kuchinja.

5.Kutariswa kwehuwandu hwekuita kwePWHT

Post-weld kupisa kurapwa hakubatsiri zvachose.Kazhinji, post-weld kupisa kurapwa kunobatsira pakubvisa kushushikana kwasara, uye inongoitwa kana paine zvakanyanya zvinodikanwa zvekunetsekana ngura.Nekudaro, kuomarara kwekuedza kwemuenzaniso kunoratidza kuti mushure-weld kupisa kurapwa hakuna kunaka kune kuomarara kwesimbi yakaiswa uye weld-yakakanganiswa nzvimbo yekupisa, uye dzimwe nguva kutsemuka kwepakati pegranular kunogona kuitika mukati mehupfu hwezviyo zvekupisa kwekupisa- yakakanganiswa nzvimbo.

Uyezve, PWHT inotsamira pakudzikiswa kwesimba rezvinhu pakupisa kwepamusoro kuti uwane zororo rekushushikana.Nokudaro, panguva yePWHT, chimiro chinogona kurasikirwa nekuoma.Kune zvimiro zvinotora yakazara kana chidimbu PWHT, iyo weldment pakupisa kwakanyanya kunofanirwa kutariswa kusati kwaitwa kupisa.kutsigira kugona.

Naizvozvo, kana uchifunga nezve kuita post-weld kupisa kurapwa, zvakanakira uye zvakaipira zvekupisa kurapwa zvinofanirwa kuenzaniswa zvakazara.Kubva pakuona kwekushanda kwemaitiro, kune rimwe divi rekuvandudza kushanda, uye rimwe divi kuderedza kushanda.Mutongo une musoro unofanira kuitwa pahwaro hwekurangarirwa kwakadzama kwemativi maviri.

Nguva yekutumira: Jun-20-2023