Nekukurumidza kusimukira kweindasitiri yepetrochemical, simbi isina tsvina yakashandiswa zvakanyanya, izvo zvakaisawo mberi zvinodiwa zvepamusoro zvekuputira pombi nemapureti.Iyo yapfuura simbi isina tsvina arc welding primer nzira yakabviswa zvishoma nezvishoma, uye argon arc welding inoshandiswa kuprimer welding.

Argon arc welding primer yakachena uye inokurumidza kupfuura arc welding primer.Panguva imwe chete, pane zvimwe zvinetso.

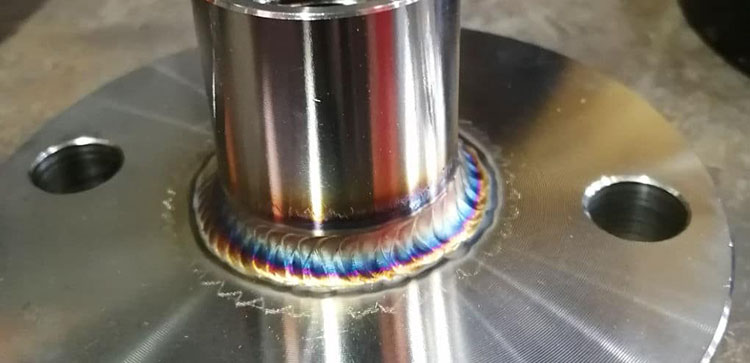

Munguva yewelding process, sezvo kuseri kwesimbi isina tsvina argon arc welding base iri nyore oxidized uye inokonzera kukanganisa, matanho ekudzivirira kumashure anofanirwa kutorwa kuti ive nechokwadi chemichini yezvivakwa uye corrosion resistance ye weld.Naizvozvo, kudzivirira kunoshanda kunofanirwa kutorwa kana uchipisa simbi isina tsvina.

Nhasi tinosuma akati wandei anowanzo shandiswa Stainless simbi welding back kudzivirira nzira:

01

Back Argon Dziviriro Nzira

Inowanzo shandiswa magasi ekudzivirira anogona kukamurwa kuita nyore argon gasi kudzivirira uye yakasanganiswa gasi kuchengetedzwa.Chimwe chikamu che argon-nitrogen yakasanganiswa gasi inonyanya kubatsira kune austenitic stainless simbi welding.Mamwe magasi anert haashandiswe nekuda kwekudhura kwawo.

Argon yekuzadza nzira yekudzivirira inzira yechinyakare yekudzivirira kumashure, ine hunhu hwekudzivirira kumashure zvirinani, nyore kubata, hutsanana hwepamusoro, uye mwero wekupasa.Iyo yakakamurwa kuita yekudzivirira yekuvharira argon yekuzadza nzira yekudzivirira, yemuno argon yekuzadza nzira yekudzivirira, yakananga kuzadza kwewelding joint, argon welding yekudzivirira nzira, nezvimwe.

1. Chivharo chekudzivirira chakazadzwa neArgon kudzivirira nzira

Iyi nzira inowanzoshandiswa musimbi isina simbi welding yemaplate uye mapaipi makuru-diameter.Chivharo chekudzivirira chakabatanidzwa kune pombi yesimbi uye argon gas hose.Iyo argon gas valve inovhurwa kuzadza chivharo chekudzivirira ne argon gasi.

Mumwe munhu anodiwa kuti abate pombi yesimbi semubato kuitira kuti chivharo chinodzivirira chitsvedze padziva rakanyungudutswa riri kuseri mukupindirana nekunze kwendiro kana pombi.

Nenzira iyi, rutivi rwekumashure runodzivirirwa zvinobudirira, uye kudzivirirwa kwakanyanyisa.Iyo argon gasi haidi kuvhurwa zvakanyanya, uye iyo argon gasi inoraswa zvishoma.

2. Local argon kuzadza kudzivirira

Zviri nyore kushandisa dziviriro yenzvimbo yemapaipi ane nzvimbo diki yenzvimbo uye madiki madiki.

Method: Namira welding joint yepombi ne tepi (kudzivirira kubuda kwemhepo).Nama kumativi ose epombi nesiponji, rabha, shell shell, nezvimwewo. Isa argon hose kubva kune imwe mugumo uye uzadze neargon.Imwe mugumo wepombi inonyanya kuvharwa.Dhonza gomba diki (hapana kudikanwa kwechiponji), iyo inofambisa iyo yekupedzisira welding yekubatanidza uye isingazokonzerese mazino nekuda kwekudzvinyirira kwakanyanya kwemukati.

Panguva yekuputika, kuitira kudzivirira huwandu hwegasi reArgon kubva pakubudiswa kubva kune weld seam, iyo weld sealing tepi inofanira kubvarurwa uye yakasungirirwa muzvikamu, izvo zvinogona kuderedza kuwedzera kurasikirwa kweargon gasi uye kudzivirira zvinobudirira musono weld.Zvimiro zvakaraswa, argon kuchaja inononoka, mutengo wakanyanya, nezvimwe.

3 .Direct argon kuzadza nzira yekudzivirira yejojo ye welding

Kune mapaipi akareba uye ane madhayamita akati kurei, kuzadza argon yemuno kwakanyanyisa, mhando haigone kuvimbiswa, uye mutengo weprojekiti wakanyanya.Kuti uchengetedze mari, nzira yakananga yekuzadza argon pajoini yakasungwa inogona kushandiswa.

Nzira yekugadzira mapulagi pamativi ese e weld seam

Gadzirisa chipanji kuita plug ine dhayamita yakati kurei yepombi uye batanidza zvidimbu zviviri zvesiponji newaya chinhambwe che300-400mm kuita plug kaviri.Imwe magumo epulagi yakabatanidzwa kune yakareba chidimbu chesimbi waya.

Pakufananidza, isa mapulagi pa150-200mm kumativi ese e weld kuti apinzwe.Iyo yakareba iron waya kune imwe mugumo inofanira kuva yakareba kudarika urefu hwepombi kune imwe mugumo we weld uye ibudise pombi kupera.Imwe mugumo wepombi duku yesimbi inofanira kuderedzwa uye imwe mugumo inofanira kubatanidzwa kune argon hose.Isa iyo yakatsetseka magumo muakarongedzerwa weld uye uzadze iyo ne argon.Iyo yakanakisa yekuisa kutungamira ndiyo chikamu chepamusoro, kuitira kuti pamberi pekupedzisira kubatana kwepasi weld, chubhu diki inogona kuvhomorwa kunze uye yakasungwa negasi rasara mupombi.Mushure mewelding, shandisa waya kuburitsa plug.

Mvura inonyungudika yekudzivirira pepa nzira

Pamberi pegungano, isa bepa rinonyungudika nemvura pa 150-200mm kumativi ose ejoint yewelding sechisimbiso.Mushure mekugadzirisa, shandisa imwechete inflatable welding nzira seponji plug.Kana pombi ichiyedzwa hydraulic pressure, bepa rinonyungudika nemvura rinonyunguduka uye roburitswa nemvura.

4. Argon gasi kudzivirira kutonga

Iyo inodzivirira iyo argon gasi inogona kutongwa maererano nemuvara wemukati weld, kuitira kuti mushandisi anogona kugadzirisa argon gasi maererano nemuvara kuti uwane yakanakisa kudzivirira.Iwo mavara machena negoridhe, uye grey nedema ndiwo akaipisisa.

5. Kuchengetedza kweStainless Steel Back Protection

(1) Pamberi peargon arc welding, kumashure kweiyo weldment kunofanirwa kuchengetedzwa nekuizadza neargon pamberi.Kuyerera kunofanira kunge kwakakura.Mushure mokunge mhepo yabudiswa, chiyero chekuyerera chichaderera zvishoma nezvishoma.Munguva yekugadzira, pombi inofanira kuzadzwa ne argon nguva dzose.Iyo argon hose inogona kusunungurwa chete mushure mekugadzirisa kwapera kuitira kuti weld ichengetedzwe zvakanaka.

Mukuwedzera, kunyanya kukoshesa kunofanira kubhadharwa kune chokwadi chokuti welding inogona kuitwa chete mushure mokunge mhepo yapera, kana zvisina kudaro kudzivirira kwekuzadza argon kuchakanganiswa.

(2) Iyo argon gasi inoyerera mwero unofanirwa kuve wakakodzera.Kana chiyero chekuyerera chiri chidiki, kuchengetedzwa hakuna kunaka, uye kumashure kwe weld kuri nyore oxidized;kana chiyero chekuyerera chakanyanyisa, kukanganisa kwakadai se concavity yemudzi we weld ichakonzerwa, inokanganisa welding quality.

(3) Iyo argon gas inlet inofanira kuiswa yakaderera sezvinobvira muchikamu chakavharwa, uye gomba rekubuda kwemhepo rinofanira kuiswa zvishoma zvishoma muchikamu chepombi yakavharwa.Nemhaka yokuti argon inorema kudarika mhepo, kuzadza argon kubva panzvimbo yakaderera kunogona kuvimbisa kuwanda kwepamusoro, uye iyo inodzivirira yekuzadza argon ichava nani.

(4) Kuti uderedze kurasikirwa kweargon gasi mupombi kubva pakakoromo pakati pemajoini, iyo inokanganisa mhedzisiro yekudzivirira uye inowedzera mutengo, tepi inogona kusungirirwa pamwe nepakati pakati pemajoini ewelding pamberi pekuisa, ichisiya chete kureba. kune imwe inopfuurira welding newelder, uye kubvisa tepi paunenge uchipisa.

02

Self-shielding welding wire protection method

The self-protected welding wire kumashure ndeye welding wire ine coating.Munguva yewelding, jira rayo rekudzivirira richatora chikamu mukudzivirira kwakakwana kwepamberi neshure kwedziva rakanyungudutswa, richigadzira dense yekudzivirira kudzivirira kumashure kwe weld bead kubva kune oxidized.Iyi yekudzivirira inodonha yega mushure mekutonhodza, uye inocheneswa nekuyedzwa panguva yekumanikidza bvunzo.ichacheneswa.

Nzira yekushandisa yemhando iyi yewaya yewelding yakangofanana neyakajairika argon arc welding solid core waya, uye kuita kwesimbi weld kunogona kuzadzisa zvinodiwa.

Iyo yekuzvidzivirira welding waya haina kuganhurirwa neakasiyana-siyana welding mamiriro, zvichiita kuti welding kugadzirira nekukurumidza uye nyore.Nekudaro, nekuda kwekupfekedzwa kuri pamusoro pewaya yewelding, pachava nekusagadzikana kana vashandi vewelding vachiishandisa.

Nekuda kwekusapindirana uye welding matekiniki asina kukodzera kune yakavharwa welding waya, kuremara kwakadai senge concavities dzimwe nguva kunoitika.Naizvozvo, pane zvimwe zvinodikanwa zvehunyanzvi hwekushanda kwevashandi vewelding uye matekiniki.Self-shielding wire inonyanya kushandiswa kune primers nekuda kwekudhura kwayo.

Uye zvakare, kune akawanda mabhureki e-self-shielding welding waya pamusika kusarudza kubva, uye kushanda kwavo kwakasiyanawo.

Nguva yekutumira: Sep-21-2023