Iyo yakanyura arc welding process ndiyo yakanyanya kunaka sarudzo munzvimbo dzakakosha dzekushandisa dzemapaipi, midziyo yekumanikidza uye matangi, kugadzira track uye kuvaka kukuru.Iyo ine yakareruka imwe waya fomu, mbiri waya chimiro, akateedzana mbiri waya chimiro uye akawanda waya chimiro.

Iyo yakanyura arc welding process inogona kubatsira vashandisi mune akawanda welding application, kubva pakuwedzera kubereka kusvika kune yakagadziridzwa mamiriro ekushanda kune inowirirana mhando nezvimwe.Simbi yekugadzira zvirimwa zviri kufunga kuita shanduko kune yakanyura arc welding process inofanirwa kufunga nezve akawanda mabhenefiti anogona kuwanikwa kubva mukuita uku.

Ruzivo rwekutanga rwe submerged arc welding

Iyo yakanyura arc welding process yakakodzera kune inorema maindasitiri application zvinodiwa zvepombi, kumanikidza ngarava nematangi, kuvaka locomotive, inorema kuvaka / kuchera.Yakanakira maindasitiri anoda kugadzirwa kwepamusoro, kunyanya ayo anosanganisira welding yezvinhu zvakakora kwazvo, izvo zvinogona kubatsirwa zvakanyanya kubva kune yakanyudzwa arc welding process.

Yayo yakakwirira deposition mwero uye kumhanya kwekufamba kunogona kuve nemhedzisiro yakakura pakubudirira kwevashandi, kushanda nesimba uye mutengo wekugadzira, inova imwe yemabhenefiti akakosha eiyo yakanyudzwa arc welding process.

Zvimwe zvakanakira zvinosanganisira: mawelds ane akanakisa kuumbwa kwemakemikari uye michina zvivakwa, kushoma arc kuoneka uye yakaderera welding fume, yakagadziridzwa nharaunda yebasa kunyaradza, uye yakanaka weld chimiro uye mutsara wechigunwe.

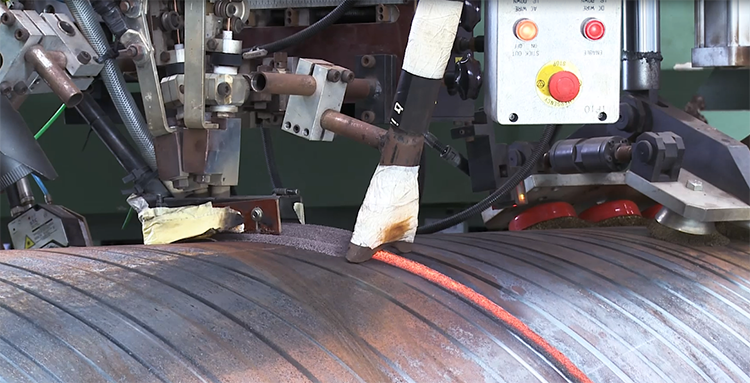

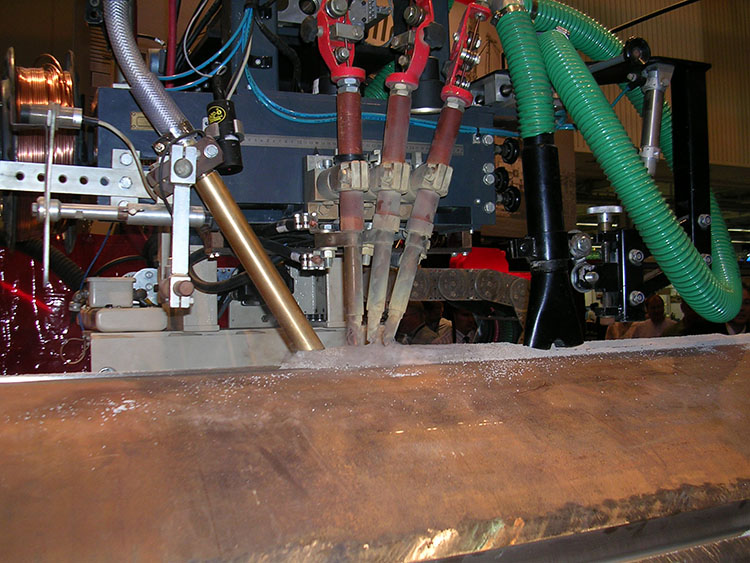

Submerged arc welding inzira yekudyisa waya inoshandisa granular flux kuparadzanisa arc kubva kumhepo.Sezvinoratidzwa nezita racho, iyo arc inovigwa mukuyerera, zvichireva kuti kana ma paramita akaiswa, iyo arc haionekwe nekuyerera kweinotevera layer yekuyerera.

Waya inogara ichidyiswa netochi inofamba ichitevedza weld.Kupisa kweArc kunonyungudutsa chikamu chewaya, chikamu chekuyerera uye nheyo yezvinhu kuti iite dziva rakanyungudutswa, iro rinoita kuti riite weld yakavharwa nedhiri rewelding slag.

Ukobvu hwemhando yewelding material ndeye 1/16 “-3/4”, inogona kuve 100% yekupinda welding kuburikidza nesingle pass welding, kana ukobvu hwemadziro husina kuganhurirwa, inogona kuve yakawanda-pass welding, uye kuita zvakakodzera. pre-kurapwa sarudzo ye weld, uye sarudza yakakodzera waya flux musanganiswa.

Flux uye kusarudzwa kwewaya

Kusarudza iyo chaiyo flux uye waya kune imwe yakanyura arc welding process kwakakosha kuti uwane mibairo yakanaka neicho maitiro.Kunyangwe iyo yakanyura arc welding process yega inoshanda, kugadzirwa uye kugona kunogona kuwedzerwa kunyangwe zvichienderana newaya uye flux inoshandiswa.

Iyo flux haingodziviriri dziva re weld, asi inobatsirawo pakuvandudzwa kweiyo mechanical properties uye kubereka kwe weld.Iko kuumbwa kwe flux isimba guru pane izvi zvinhu, zvichikanganisa ikozvino kutakura simba uye slag kusunungurwa.Parizvino kutakura kugona kunoreva kuti iyo yepamusoro inogoneka yekuisa mashandiro uye yemhando yepamusoro weld mbiri inogona kuwanikwa.

Iyo slag kuburitswa kweimwe flux inokanganisa kusarudzwa kwe flux nekuti mamwe fluxes anokodzera zvirinani kune mamwe madhizaini ekushongedza kupfuura mamwe.

Flux sarudzo dzekusarudza dzakadzika arc welding dzinosanganisira inoshanda uye isina kwayakarerekera mhando dzewelding.Musiyano wekutanga ndewekuti iyo inoshanda flux inoshandura chemistry ye weld, nepo iyo yakasarudzika flux isingaite.

Active flux inoratidzwa nekubatanidzwa kwesilicon uye manganese.Izvi zvinhu zvinobatsira kuchengetedza weld tensile simba pakupisa kwekupisa, kubatsira weld kuramba yakatsiga pakumhanya kwekufamba uye kupa yakanaka slag kuburitswa.

Pakazere, inoshanda flux inogona kubatsira kudzikisira njodzi yekushata welding mhando, pamwe neinodhura post-weld yekuchenesa uye rework.

Ramba uchifunga, zvisinei, kuti inoshanda flux inowanzova yakanakira imwe chete kana kaviri pass welding.Neutral fluxes zviri nani kune makuru akawanda-pass welds nekuti anobatsira kudzivirira kuumba brittle, crack-sensitive welds.

Kune akawanda mawaya sarudzo dzeakanyura arc welding, imwe neimwe iine zvakanakira nezvayakaipira.Mamwe mawaya akagadzirirwa welding pakupisa kwakakwira, nepo mamwe akagadzirwa kuti ave nealloys anobatsira flux kuchenesa weld.

Cherechedza kuti makemikari emagetsi ewaya uye kupindirana kwekupisa kwekupisa kunogona kukanganisa maitiro emagetsi e weld.Kubudirira kunogonawo kuvandudzwa zvikuru nekuzadza kusarudzwa kwesimbi.

Semuenzaniso, kushandisa simbi-cored waya ine yakadzika arc welding process inogona kuwedzera deposition kugona ne15 kusvika 30 muzana zvichienzaniswa nekushandisa waya yakasimba, nepo ichipa yakafara, isina kudzika yekupinda profiles.

Nekuda kwekumhanya kwayo kukuru, iyo simbi cored wire zvakare inoderedza kupisa kupinza kuti kuderedze njodzi yewelding kukanganisa uye kupisa-kunze.Kana usina chokwadi, bvunza mugadziri wesimbi anozadza kuti aone kuti ndeapi waya uye musanganiswa we flux wakanakira imwe application.

Nguva yekutumira: Jun-27-2023