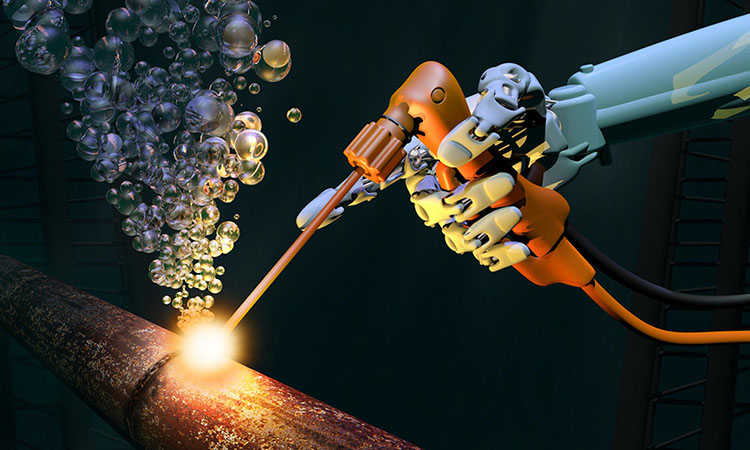

Kune marudzi matatu epasi pemvura welding: yakaoma nzira, yemvura nzira uye imwe yakaoma yakaoma nzira.

Dry welding

Iyi inzira iyo kamuri huru yemhepo inoshandiswa kuvhara weldment, uye welder anoita welding muimba yemhepo.Sezvo welding inoitwa muchikamu chakaoma gasi, kuchengetedzwa kwayo kuri nani.Kana hudzamu huchipfuura dhivha yemhepo, mazhenje anogadzirwa nyore nyore nekuda kwekuwedzera kwemhepo yeokisijeni yemunharaunda munzvimbo yemhepo.Nokudaro, gasi inert kana semi-inert inofanira kushandiswa muimba yegesi.Munguva yakaoma welding, ma welders anofanirwa kupfeka zvakakosha zvisingaite moto uye yakakwirira tembiricha inodzivirira inodzivirira.Kuenzaniswa nekunyorova uye chidimbu chakaomeswa welding, yakaoma welding ine yakanakisa chengetedzo, asi kushandiswa kwayo kudiki uye kushandiswa kwayo hakusi kwese.

partial dry welding

Nzira yemunharaunda yakaoma inzira yekudzivirira pasi pemvura iyo iyo welder inoita welding mumvura uye inochera mvura yemvura yakakomberedza nzvimbo yekugadzira, uye matanho ayo ekuchengetedza akafanana neaya emvura.

Sezvo nzvimbo yakaoma nzira ichiri pasi pekutsvakurudza, kushandiswa kwayo hakusati kwapararira.

Welding welding

Wet welding inzira yepasi pemvura yewelding iyo iyo welding inosveta zvakananga pasi pemvura pachinzvimbo chekuburitsa mvura nemazvo ichitenderedza nzvimbo yewelding.

Kupisa kweArc pasi pemvura kwakafanana neyakanyura arc welding, uye inotsva mumabhuru emhepo.Kana iyo electrode ichipisa, kupfeka pa electrode kunogadzira sleeve inogadzirisa mabhubhu emhepo uye nokudaro inodzikamisa arc.Kuti uite kuti electrode ipise yakadzikama pasi pemvura, zvinodikanwa kupfekedza humwe ukobvu hwekuputira pane electrode core uye kuipfekedza neparafini kana zvimwe zvinhu zvisingaite mvura kuita kuti electrode isapinda mvura.Mabhubhu ihaidhirojeni, okisijeni, mhute yemvura uye mabhubhu anogadzirwa nekupisa kwema electrode coatings;mamwe maokisidhi anogadzirwa nehutsi hunoputika.Kuti ukunde kuomerwa kwearc ignition uye kudzikamiswa kwearc kunokonzerwa nekutonhodza kwemvura uye kudzvanywa, iyo arc ignition voltage yakakwira kupfuura iri mumhepo, uye ikozvino i15% kusvika 20% yakakura pane welding ikozvino mumhepo.

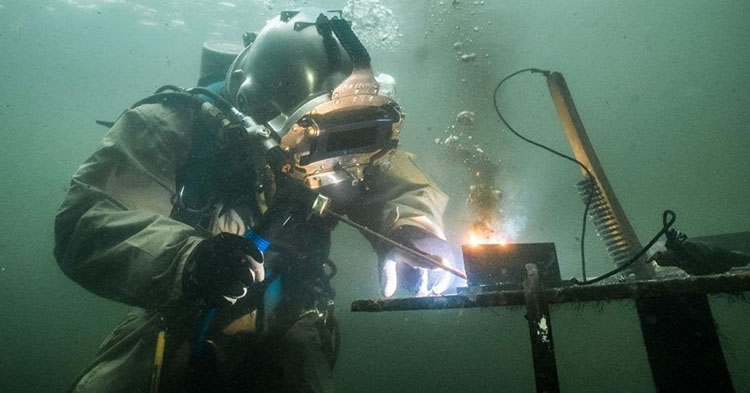

Kuenzaniswa neyakaoma uye chidimbu yakaoma welding, pasi pemvura wet welding ine yakanyanya kushandiswa, asi chengetedzo ndiyo yakaipisisa.Nekuda kweiyo conductivity yemvura, kuchengetedzwa kubva kumagetsi kuvhunduka ndeimwe yeakanyanya kuchengetedzwa kunetseka kwekunyorova welding.

Wet pasi pemvura welding inoitwa zvakananga mumvura yakadzika, ndiko kuti, pasi pemamiriro ekuti hapana mechanical chipingamupinyi pakati penzvimbo yewelding nemvura.Iyo welding haingobatanidzwe chete neambient water pressure, asiwo yakanyanyisa kunyoroveswa nemvura yakapoteredza.

Kunyangwe kunyorova kwemvura pasi pemvura kuri nyore uye kuchinjika, uye kunoda midziyo yakapusa uye mamiriro, nekuda kwekutonhora kwakasimba kweiyo welding arc, dziva rakanyungudutswa, electrode uye welding simbi nemvura, kugadzikana kwearc kunoparadzwa, uye chimiro che weld hachina kunaka. .Iyo yakaomeswa nzvimbo inoumbwa munzvimbo yewelding inopisa-yakakanganiswa nzvimbo, uye yakawanda yakawanda yehydrogen inopindirwa muarc column uye dziva rakanyungudutswa panguva yewelding process, izvo zvinogona kutungamirira kune hurema hwakadai sewelding mitswe uye pores.Naizvozvo, kunyorova kwepasi pemvura welding kunowanzo shandiswa munzvimbo dzisina kudzika dzemvura dzine mamiriro akanaka egungwa uye welding yezvikamu zvisingade kushushikana kwakanyanya.

Nzvimbo yepasi pemvura inoita kuti pasi pemvura welding process ive yakaoma zvakanyanya kupfuura iyo land welding process.Kuwedzera kune welding tekinoroji, inosanganisirawo zvinhu zvakawanda senge diving operation tekinoroji.Hunhu hwe underwater welding ndeidzi:

1. Kuonekwa kushoma.Kutorwa, kutariswa uye kudzokororwa kwechiedza nemvura kwakasimba kudarika mhepo.Naizvozvo, chiedza chinopera simba nokukurumidza kana chichipararira mumvura.Pamusoro pezvo, huwandu hukuru hwemabhuru uye utsi zvinogadzirwa zvakatenderedza arc panguva yewelding, zvichiita kuti arc yepasi pemvura yakaderera zvakanyanya mukuonekwa.Welding yepasi pemvura inoitwa munzvimbo ine madhaka yegungwa nemugungwa ine jecha nemadhaka, uye kuonekwa mumvura kunotonyanya kuipa.

2. Musono we weld une high hydrogen content, uye hydrogen ndiye muvengi we welding.Kana iyo hydrogen yemukati muwelding ichipfuura kukosha kunobvumidzwa, zviri nyore kukonzera makatsemuka uye kunyange kutungamirira kukuvadzwa kwechimiro.Iyo arc yepasi pemvura inokonzeresa kupisa kwemvura yakapoteredza, zvichikonzera kuwedzera kwehydrogen yakanyungudutswa muweld.Hunhu husina kunaka hwemajoini akasungwa epasi pemvura electrode arc welding haaparadzanisiki kubva kune yakakwira hydrogen.

3. Iko kutonhora kunokurumidza.Paunenge uchipisa pasi pemvura, kudziya kwemvura yegungwa kunenge kwakakwirira, iyo inopeta ka20 kupfuura yemhepo.Kana iyo yakanyorova nzira kana yemunharaunda nzira inoshandiswa pasi pemvura welding, workpiece kuti welded zvakananga mumvura, uye quenching mugumisiro wemvura pamusoro weld zviri pachena, uye zviri nyore kubudisa yakakwirira-kuoma kwakaoma chimiro.Nokudaro, iyo inotonhora inogona kudziviswa chete kana yakaoma welding inoshandiswa.

4. Pesvedzero yekumanikidza, sezvo kumanikidza kunowedzera, iyo arc column inove yakatetepa, hupamhi hweweld bead inova diki, kureba kweiyo weld seam inowedzera, uye kuwanda kweiyo conductive medium kunowedzera, izvo zvinowedzera kuoma kweionization. , iyo arc voltage inowedzera zvichienderana, uye arc kugadzikana Yakaderedzwa, yakawedzera splash uye utsi.

5. Kuenderera mberi kushanda kwakaoma kuziva.Nekuda kwekupesvedzera uye kuganhurirwa kwenzvimbo yepasi pemvura, muzviitiko zvakawanda, nzira yewelding yechikamu chimwe uye kumira kwechikamu chimwe inofanira kugamuchirwa, zvichikonzera kuregedza welds.

Kuchengeteka kwekunyorova kwepasi pemvura welding kwakaipisisa kupfuura uko kuri panyika.Matanho makuru ekuchengetedza ndeaya:

Yakananga ikozvino inofanira kushandiswa pasi pemvura welding, uye alternating current inorambidzwa.Iyo isina-load voltage inowanzoita 50-80V.Kudzora midziyo yemagetsi inosangana yakananga nema diving welders inofanirwa kushandisa yekuzviparadzanisa ne transformer uye kuchengetedzwa nekuremerwa.Vasati vaita diving welders vatanga kushanda kana panguva yekuchinja ma electrode, vanofanirwa kuzivisa vashandi vepasi kuti vadimbure dunhu.Diving welders vanofanirwa kupfeka zvipfeko zvekudzivirira zvakakosha uye magurovhosi akakosha.Munguva yekupisa kwearc uye kuenderera mberi kwearc, maoko anofanirwa kudziviswa kubva pakubata maworkpieces, tambo, welding rods, etc. Kana welding pane mhenyu chimiro, ikozvino pane iyo dhizaini inofanira kutanga yagurwa.Munguva yekushanda pasi pemvura welding, kuchengetedzwa kwehutsanana hwevashandi, kunyanya kuchengetedzwa kwemadhorobha uye kudzivirira kwekupisa kunofanirwa kupihwa.Gara uchitarisa maitirwo ekudzivirira uye kusapinda mvura kwemidziyo yepasi pemvura welding, welding tongs, tambo, nezvimwe.

Nguva yekutumira: Jul-12-2023