Electrode arc welding ndiyo inonyanya kushandiswa welding nzira mukugadzira maindasitiri.Simbi inofanira kuiswa danda rimwe, uye electrode ndiyo imwe danda.Kana matanda maviri ari padhuze kune mumwe nemumwe, arc inogadzirwa.Kupisa kunokonzerwa nearc discharge (inowanzozivikanwa se arc combustion) inoshandiswa kubatanidza electrode ne workpieces inonyunguduka imwe neimwe uye inogadzira weld mushure mekunyunguduka, kuitira kuti uwane nzira yekubatanidza ine simba rakasimba.

Mufananidzo 1. Nhoroondo ye welding

Nhoroondo pfupi

Mushure mekuedza kwakawanda kwewelding mukutanga kwezana ramakore rechi 19, mumwe murume wechiRungu ainzi Willard akatanga kuwana patent ye arc welding muna 1865. Akashandisa electric current kuti apfuure nepakati pezvidimbu zviviri zvesimbi kuti zvibudirire, uye mumakore angangoita makumi maviri gare gare, munhu wokuRussia. anonzi Bernard akawana patent yearc welding process.Akachengetedza arc pakati pekabhoni pole uye workpieces.Apo iyo arc yaishandiswa nemaoko kuburikidza nekubatana kwezvishandiso zvebasa, ma workpiece aifanira kuiswa welded akabatanidzwa pamwechete.Mumakore ekuma1890, simbi yakasimba yakagadzirwa se electrode, iyo yakapedzwa mudziva rakanyungudutswa uye ikava chikamu chesimbi ye weld.Nekudaro, okisijeni nenitrogen mumhepo zvakagadzira maokisidhi anokuvadza uye nitrides musimbi yeweld., Saka zvichitungamira kune urombo hwekushongedza mhando.

Mukutanga kwezana remakore rechi20, kukosha kwekudzivirira arc kudzivirira kupindira kwemhepo kwave kwaonekwa, uye kushandiswa kwearc kupisa kunoparadza kuvhara mu electrode yekudzivirira gasi shield yakava nzira yakanakisisa.Pakati pemakore ekuma1920, electrode yakavharidzirwa yakagadzirwa, iyo yakavandudza zvikuru kunaka kwesimbi yakashongedzwa.Panguva imwecheteyo, inogona zvakare kuve yakakosha shanduko yearc welding.Midziyo mikuru mukuita welding inosanganisira yemagetsi welding muchina, welding tongs uye kumeso mask.

Mufananidzo 2. Nheyo yewelding

Mufananidzo 2. Nheyo yewelding

Principle

Iyo welding arc inofambiswa neiyo welding simba sosi.Pasi pechiito cheimwe voltage, chinhu chakasimba uye chinogara kwenguva refu chinobuda chinoitika pakati pe electrode (uye kupera kwewaya welding kana tsvimbo yemoto) uye workpiece.Izvo zvakakosha zvewelding arc igasi conduction, ndiko kuti, gasi risina kwariri munzvimbo iyo arc iripo inosvibiswa kuita maioni ane chaji yakanaka uye maerekitironi anochajiswa zvisina kunaka pasi pekuita kweimwe voltage, iyo inonzi ionization.Zvimedu zviviri zvinochajiswa zvakanangidzirwa kumatanda maviri.Directional movement inoita kuti gasi remuno riite magetsi kuita arc.Iyo arc yemagetsi inoshandura simba remagetsi kuita kupisa, iro rinopisa nekunyungudusa simbi kuti iite mubatanidzwa wakasungwa.

Mushure mokunge arc inokurudzirwa kuti "inopisa", nzira yekubuda pachayo inogona kubudisa masheji anopomerwa anodiwa kuti atsigire kubuda, iyo inozvigadzirisa yega.Uye iyo arc discharge process ine yakaderera voltage, yakakwira ikozvino, yakanyanya tembiricha uye yakasimba luminescence.Nekuita uku, simba remagetsi rinoshandurwa kuita kupisa, mechanical uye chiedza simba.Welding inonyanya kushandisa simba rayo rinopisa uye remagetsi kuzadzisa chinangwa chekubatanidza simbi.

Munguva yewelding, iyo arc inopisa pakati petsvimbo yewelding uye welding workpieces, ichinyungudutsa maworkpieces uye iyo electrode core kuita dziva rakanyungudutswa.Panguva imwecheteyo, iyo electrode coating inonyungudutswa, uye kemikari inoitika kuti igadzire slag uye gasi, inodzivirira kupera kwe electrode, madonhwe, dziva rakanyungudutswa uye yakakwirira-tembiricha weld simbi.

Main classification

Yakajairika arc welding nzira dzinosanganisira Shielded Metal Arc Welding (SMAW), Submerged Arc Welding (SAW), Gasi Tungsten Arc Weld (GTAW kana TIG welding), Plasma Arc Welding (PAW) uye Gasi Metal Arc Welding (GMAW, MIG kana MAG welding). ) nezvimwewo.

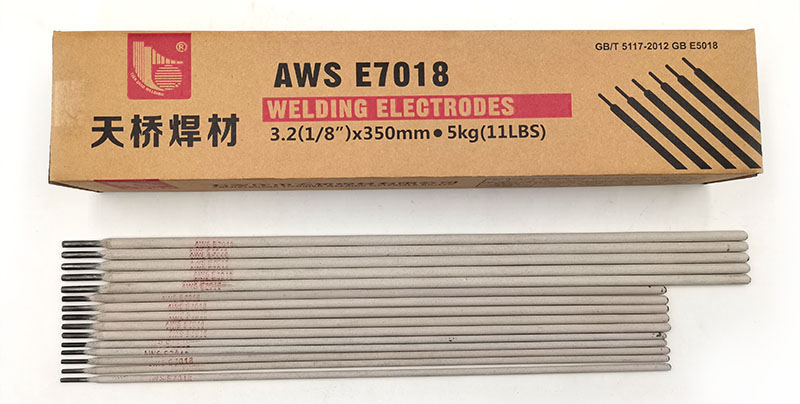

Mufananidzo 3. E7018 welding electrode

Shielded Metal Arc Welding (SMAW)

Shielded metal arc welding inoshandisa electrode uye workpiece sema electrode maviri, uye kupisa uye kuvhuvhuta simba rearc rinoshandiswa kunyungudutsa workpiece panguva yewelding.Panguva imwecheteyo, pasi pekuita kwekupisa kwearc, kuguma kwe electrode kunonyungudutswa kuita donhwe, uye workpiece inonyungudutswa zvishoma kuti iite gomba reovha rakazadzwa nesimbi yemvura.Iyo yakanyungudutswa simbi yakanyungudutswa uye donhwe rebasa rinogadzira dziva rakanyungudutswa.Munguva yekugadzira, iyo yekuputira uye isiri-simbi ndiyo inclusions inonyungudika mumwe nemumwe uye inoumba isiri-simbi inovhara pamusoro peiyo weld kuburikidza nemakemikari shanduko inonzi slag.Sezvo arc inofamba, dziva rakanyungudutswa rinotonhora uye rinooma kuita weld.Tine akasiyana welding electrode yeSMAW, inonyanya kufarirwa mamodheruE6010, E6011, E6013, E7016, E7018,uye nokudasimbi isina ngura, simbi, yakaoma pamusoroetc.

Mufananidzo 4. Yakanyura arc welding

Mufananidzo 4. Yakanyura arc welding

Submerged Arc Welding (SAW)

Submerged arc welding inzira iyo arc inopisa pasi pe flux layer yewelding.Iyo simbi electrode inoshandiswa mumvura yakanyura arc welding iwaya isina chinhu inongodyirwa mukati pasina kukanganisa.Kazhinji, welding trolley kana mamwe ma mechanic nemagetsi maturusi anoshandiswa kuona otomatiki kufamba kwearc panguva yewelding process.Iyo arc ye submerged arc welding inopisa pasi pegranular flux.Kupisa kwearc kunonyunguduka uye kunopisa zvikamu zvakanangana nearc yebasa rekushanda, kupera kwetambo yewelding uye kuyerera, uye mhute yesimbi uye inoputika inoputika kuita chivharo chakavharwa chakakomberedza arc.Kusvirwa mumhango iyi.Iyo mhango yakakomberedzwa nefirimu ye slag inoumbwa ne slag inogadzirwa ne flux melting.Iyi firimu ye slag haisi kungoparadzanisa mhepo kubva pakusangana nearc uye dziva rakanyungudutswa, asiwo inodzivirira arc kubva kunze.Waya yewelding inodziya nekunyungudutswa nearc inowira muchimiro chemadonhwe uye inosanganiswa nesimbi yakanyungudutswa yeworkpiece kuita dziva rakanyungudutswa.Iyo shoma shoma slag inoyangarara padziva rakanyungudutswa.Pamusoro pekusarudzika kwemechani uye kudzivirira kwesimbi yedziva yakanyungudutswa, iyo yakanyungudutswa slag zvakare inosangana nemetallurgical reaction neyakanyungudutswa dziva simbi panguva yewelding process, nekudaro ichikanganisa kuumbwa kwekemikari yeweld simbi.Arc inoenda kumberi, uye simbi yedziva yakanyungudutswa inotonhora zvishoma nezvishoma uye inopenya kuita weld.Mushure mekunge slag yakanyungudutswa ichiyangarara pamusoro pedziva rakanyungudutswa ratonhora, ganda reslag rinoumbwa kuti rirambe richidzivirira weld pakupisa kwepamusoro uye kudzivirira kuti isaite oxidized.Isu tinopa iyo flux yeSAW,SJ101,SJ301,SJ302

Mufananidzo 5. Gasi Tungsten Arc Weld-TIG

Mufananidzo 5. Gasi Tungsten Arc Weld-TIG

Gas Tungsten Arc Weld/Tungsten Inert Gasi Welding (GTAW kana TIG)

TIG welding inoreva nzira yearc welding inoshandisa tungsten kana tungsten alloy (thorium tungsten, cerium tungsten, etc.) se electrode uye argon segasi rinodzivirira, rinodaidzwa kuti TIG welding kana GTAW welding.Panguva yekuputika, simbi yekuzadza inogona kuwedzerwa kana kusawedzerwa maererano ne groove fomu ye weld uye kushanda kwesimbi ye weld.Filler metal inowanzowedzerwa kubva kumberi kwearc.Nekuda kwekusarudzika kwealuminium-magnesium uye alloy zvinhu, AC tungsten arc welding inodiwa pawelding, uye DC tungsten arc welding inoshandiswa kune zvimwe zvinhu zvesimbi.Kuti udzore kupinza kwekupisa, pulsed argon tungsten arc welding inonyanya kushandiswa zvakanyanya.Inonyanya kushandiswa TIG welding waya dziriAWS ER70S-6, ER80S-G,ER4043,ER5356,HS221uye etc.

Mufananidzo 5. Plasma Arc Welding

Mufananidzo 5. Plasma Arc Welding

Plasma Arc Welding (PAW)

Plasma arc imhando yakakosha yearc.Iyo arc zvakare ndeye tungsten kana tungsten alloy (thorium tungsten, cerium tungsten, nezvimwewo) searc electrode, uchishandisa argon seyakadzivirira gasi, asi tungsten electrode haibude kunze kwemuromo, asi inodzoreredza Mukati memuromo, iyo muromo. inonyoroveswa nemvura, inozivikanwawo semvura-yakatonhodzwa nozzle.Iyo inert gasi yakakamurwa kuita zvikamu zviviri, chimwe chikamu gasi rinobudiswa pakati pe tungsten electrode uye mvura-yakatonhorera nozzle, inonzi ion gasi;chimwe chikamu igasi rinobudiswa pakati pemvura-yakatonhodzwa nozzle uye yekudzivirira gasi hood, inonzi Shielding gas, uchishandisa plasma arc sechinhu chinopisa chekupisa, kucheka, kupfapfaidza, kuisa pamusoro, nezvimwe.

Mufananidzo 5 Metal-Inert Gas Welding

Mufananidzo 5 Metal-Inert Gas Welding

Metal Inert Gasi Welding (MIG)

MIG welding zvinoreva kuti waya yewelding inotsiva tungsten electrode.Iyo welding wire pachayo ndeimwe yemapuranga e-arc, ichiita basa rekufambisa kwemagetsi uye arcing, uye panguva imwechete sechinhu chekuzadza, icho chinoramba chichinyunguduka uye chizere mu weld pasi pechiito che arc.Iyo gasi inodzivirira inowanzoshandiswa kutenderedza arc inogona kuva inert gasi Ar, iyo inoshanda gasi CO2, kana iyo Ar+CO2gasi rakasanganiswa.MIG welding inoshandisa Ar sekudzivirira gasi inonzi MIG welding;MIG welding inoshandisa CO2sezvo kudzivirira gasi kunonzi CO2welding.Inonyanya kufarirwa MIG ndeyeAWS ER70S-6, ER80S-G.

Nguva yekutumira: Aug-17-2021