Welding electrode iri a simbishamhu inonyungudika uye izere pajoinhi yeiyo yekunamatira-chidimbu chebasa panguva yemoto gasi kana iwo magetsi emagetsi. Izvo zvinhu zveiyo electrode zvinowanzo fanika neicho chinhu chebasa-chidimbu.

Pano tinosvika pakunzwisisa kuti sei neiyo welding electrode inoumbwa ne:

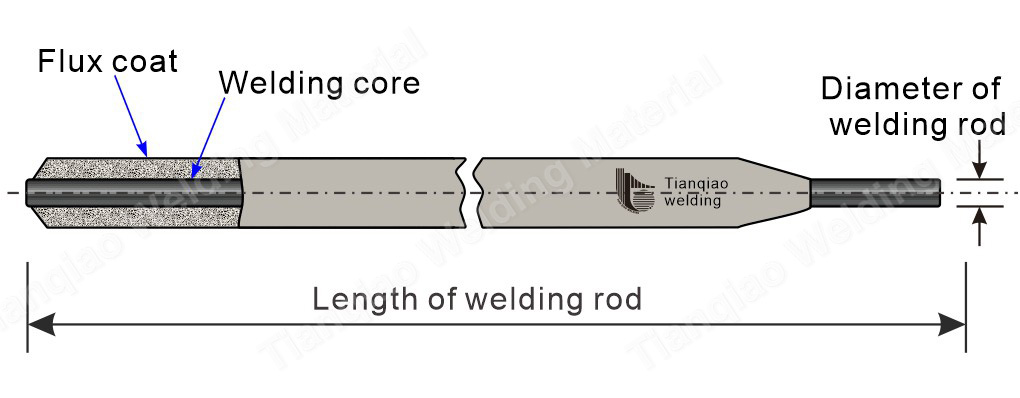

Mufananidzo 1 Maumbirwo eTianqiao Welding electrode

Iyo yemagetsi electrode ndeyeyekunyungudika electrode yakaputirwa nekumhanyisa ye arc welding yeiyo tsvimbo yekutsiga. Iyo inoumbwa neyekunamatira uye yekutenderera musimboti.

Iyo simbi simbi yakafukidzwa nekupfekera mudanda rewelding inonzi iyo Welding moyo. Welding musimboti unowanzo kuve simbi waya ine imwe hurefu uye dhayamita.

Mufananidzo 2 Core yeTianqiao Welding electrode

Mabasa maviri epakati

1. Kuitisa Welding yazvino uye kuburitsa arc kushandura magetsi simba kuita kupisa.

2. Musimbi wekusungira pachawo unonyungudika sesimbi yekuzadza uye fuses nesimbi yemvura simbi kugadzira weld. Kana ichitenderedzwa ne electrode, simbi yepakati inobata chikamu chese weld simbi. Naizvozvo, makemikari ekuumbwa kweiyo weld musimboti inokanganisa zvakananga mhando yeiyo weld. Naizvozvo, iyo simbi waya inoshandiswa seiyo musimboti weiyo electrode ine mucherechedzo wayo uye kuumbwa kwakasiyana kwakatsanangurwa.

Electrode kupfekarinoreva unhani rukoko rinoshandiswa pamusoro penzvimbo yekutenderera. Iko kupfeka kwakaora uye kwakanyungudika muyakagadziriswa nzira yekugadzira gasi uye slag, iyo inoita chinzvimbo mukuchengetedza michina, kurapwa kwesimbi, uye kugadzirisa maitiro ekuita.

Mufananidzo 3 Kuputira kweTianqiao welding electrode

Kuumbwa kwekupfekedza kunosanganisira: zvicherwa (senge machena, fluorspar, nezvimwewo), ferroalloys nesoda mapoda (senge ferromanganese, ferro-titanium, nezvimwewo), organic zvinhu (zvakadai sehuni yehuni, cellulose, nezvimwewo), zvigadzirwa zvemakemikari (senge titanium dioxide, girazi remvura, nezvimwewo). Electrode kupfeka chinhu chakakosha mukumisikidza mhando yemawelds.

Mabasa makuru ekuputira mune yekutenderera maitiro

1. Kuvandudza kugadzikana kweye arc kupisa:

Iyo isina kuvharwa electrode haisi nyore kubatidza arc. Kunyangwe ikabatidzwa, haigone kupisa zvakaringana.

2. Chengetedza weld dziva:

Munguva yekumonera, okisijeni, nitrogen uye mvura mhute mumhepo inopinda mukati meiyo weld seam, iyo ichave nemhedzisiro yakaipa pane iyo weld seam. Kwete chete kuumbwa kwe pores, asi zvakare kudzikisira iko kweanogadzira eiyo weld, uye kunyange kukonzera kutsemuka. Mushure mekuvhara kwe electrode kwanyungudika, yakawanda gasi inogadzirwa inovhara arc nedziva rakanyungudutswa, rinozodzikisa kudyidzana pakati pesimbi yakanyungudutswa nemhepo. Kana iyo weld yatonhorera, iyo yakanyunguduka inovhara inoita rukoko rwe slag, iyo inovhara pamusoro peiyo weld, inodzivirira iyo weld simbi uye inotonhodza iyo zvishoma nezvishoma, ichideredza mukana wekuti porosity.

Tatu, kuve nechokwadi chekuti weld yakaiswa deoxidized uye yakasarudzika uye phosphorus tsvina

Kunyangwe dziviriro ichiitwa panguva yekumonera, zvichiri zvisingadzivisike kuti huwandu hweokisijeni hunopinda mudziva rakanyungudutswa kuti riite oxidize simbi uye alloy zvinhu, kupisa izvo zvigadzirwa zvealloy, uye kudzora mhando yeiyo weld. Naizvozvo, zvinodikanwa kuti uwedzere chinhu chinodzora (senge manganese, silicon, titanium, aluminium, nezvimwewo) kune iyo electrode yekupfeka kudzikisa iwo maoidhi apinda mudziva rakaumbwa.

4. Wedzera zvinhu zvinokonzeresa zvinhu zveiyo weld:

Nekuda kweiyo yepamusoro tembiricha mhedzisiro yeiyo arc, izvo zvinowedzeredza zvinhu zvesimbi yesimbi zvinozopwa uye kupiswa, izvo zvinoderedza michina maficha eiyo weld. Naizvozvo, zvinodikanwa kuti uwedzere yakakodzera alloying zvinhu kune iyo weld kuburikidza nekupfekedza kuti ubhadhare kupiswa kwakarasikirwa kweiyo alloy element uye kuona kana kugadzirisa izvo zvemakanika zvivakwa zvesimbi. Nekunamatira kweimwe simbi steels, zvinodawo kupinza chiwanikwa mukati mechisimbi kuburikidza nekupenda, kuitira kuti simbi yesimbi inogona kuve padhuze nesimbi yekuumbwa kwesimbi simbi, uye michina zvivakwa zvinogona kubata kana kutopfuura. simbi yepasi.

5.Natsiridza Welding negoho uye kuderedza spatter:

Iko electrode kupfeka ine mhedzisiro yekuwedzera iyo droplet uye kudzikisa iyo spatter. Iko kunonyungudika kweiyo electrode kupfeka kwakadzikira zvishoma pane iyo yekutenderera poindi yemukati. Nekudaro, nekuti iyo yekumisikidza musimboti iri pakati peiyo arc uye tembiricha iri yakati rebei, iyo yemukati simbi inonyunguduka kutanga, uye iyo yekunamatira inonyungudika zvishoma gare gare. Panguva imwecheteyo, sezvo kurasikirwa kwesimbi kunokonzerwa nespatter kwadzikira, iko kuisa kwekuwedzera kwakakwidziridzwa, uye neyakagadzirwa neyakagadziriswa inogadziriswazve.

Kuumbwa kweiyo welding electrode Inoenderana Vhidhiyo:

Kana zviri zvehasha dzemitengo, isu tinotenda kuti iwe unenge uchitsvaga kure nekure kune chero chinhu chingatirove. Tinogona kutaura zviri nyore tiine chokwadi chechokwadi chekuti kune yakadai mhando-yepamusoro pamitengo yakadai yemitengo isu tiri vepasi zvakatenderedza6013 Welding Tsvimbo , Mangalam Welding Muchina , Zvakaoma Kutarisana Welding Electrode, Chinangwa chedu ndechekuti "Ipa Zvigadzirwa neMhando Yakavimbika uye Nemitengo Inonzwisisika". Tinogamuchira vatengi kubva kukona dzese dzenyika kuti vatibate isu kune ramangwana hukama hwebhizinesi uye kubudirira mukuwirirana!