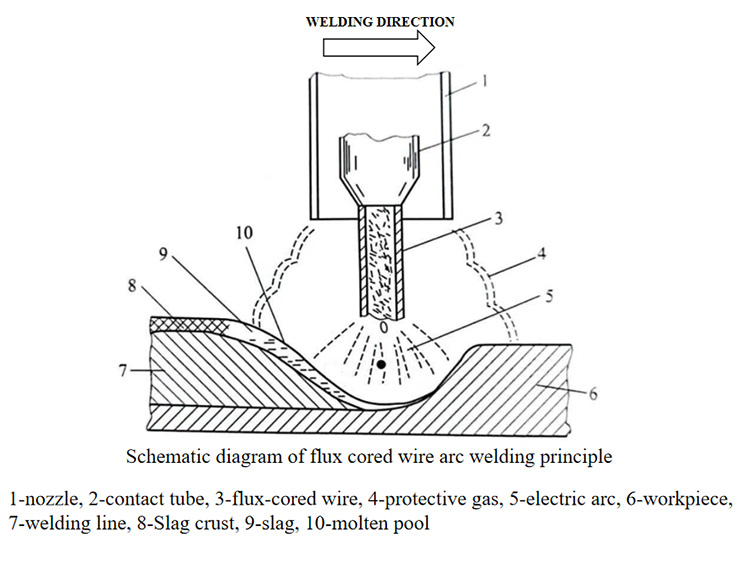

Flux-cored wire arc welding inzira yewelding inoshandisa arc pakati pe flux-cored waya uye workpiece kupisa, uye zita rayo rechirungu rinongoti FCAW.Pasi pechiito chekupisa kwearc, welding wire simbi uye workpiece zvakabatanidzwa nekunyunguduka, zvichiita dziva re weld, arc mberi mushure mekristallilization ye weld pool muswe.

Chii chinonzi flux-cored wire?Ndeapi maitiro eiyo cartridge?

Flux-cored welding wire imhando yewaya yewelding inogadzirwa nekukungurutsa simbi yakatetepa mupombi yesimbi kana yakakosha-yakaita sesimbi pombi, ichizadza pombi nezvimwe zvikamu zvehupfu, uye kudhirowa.Kuumbwa kwehupfu hwehupfu hwakafanana neye electrode coating, iyo inonyanya kuumbwa nearc stabilizing agent, slag forming agent, gas forming agent, alloying agent, deoxidizing agent, nezvimwewo.

Ndeipi basa rekuyerera muwaya ine flux-cored?

Basa rekuyerera rakafanana nere electrode coating, uye pane kunyanya anotevera marudzi.

① Dziviriro mhedzisiro yezvimwe zvinhu muwelding flux kuora, kumwe kunyungudika!Kuora kwewelding flux inoburitsa gasi, iyo inopa imwe kana yakawanda dziviriro.Iyo yakanyungudutswa inoumba slag yakanyungudutswa, inovhara pamusoro pedonhwe uye dziva rakanyungudutswa, uye simbi yemvura inoidzivirira.

② Arc stabilizer mu arc stabilizer cartridge inogona kudzikamisa arc uye kuderedza spatter rate.

③ Alloying chiito Zvimwe zve alloy zvinhu mupakati zvinogona kusanganisa weld.

④ Deoxidation alloy zvinhu zve slag zvinogona kuita nemasimbi emvura.Kuvandudza kuumbwa kwesimbi ye weld, kuvandudza maitiro ayo emagetsi.

Mukuwedzera, iyo slag yakavharwa inogonawo kuderedza kutonhora kwemvura yemvura yakanyungudutswa, kuwedzera nguva yekuvapo kwedziva rakanyungudutswa, izvo zvinobatsira kuderedza zviri mugasi rinokuvadza mu weld uye kudzivirira porosity.

Ndeapi marudzi e flux cored arc welding aripo?

Kune marudzi maviri eflux cored wire arc welding (FCAW-G) uye self-protection welding (FCAW-S), zvichienderana nekuti gasi rekudzivirira rekunze rinoshandiswa here kana kuti kwete.

Iyo gasi yakadzivirirwa welding ye flux-cored wire inowanzo shandisa kabhoni dhaibhorosi kana kabhoni dhaikisaidhi pamwe neargon segasi rinodzivirira, uye kuyerera kwewaya kunenge kuine gasi diki.Iyi nzira yakafanana neyakajairwa gasi yakadzivirirwa welding.Kuzvidzivirira welding hakudi kunze kwekudzivirira gasi.Kune huwandu hukuru hwegasi mukuyerera, uye gasi uye slag yakaora neiyo gasifier inoshandiswa kudzivirira.

Ndezvipi zvakanakira flux-cored arc welding?

Flux-cored arc welding ine zvinotevera zvakanakira.

(1) High welding chigadzirwa chakanyanya kunyunguduka kushanda zvakanaka (kusvika 85% ~ 90%), kukurumidza kunyungudika nekukurumidza;Kuwelding yakatsetseka, kumhanya kwekupotera kwakapetwa ka1.5 kuya kwemanual arc welding, uye kune dzimwe nzvimbo dzewelding, inokwana ka3-5 iyo yemanual arc welding.

② Diki splash, weld inogadzira yakanaka drug core yakawedzera arc stabilizer, saka arc kugadzikana, kupenya kudiki, yakanaka weld kuumba.Nekuti dziva rakanyungudutswa rakafukidzwa neyakanyungudutswa slag, iyo weld surface shape iri nani zvakanyanya pane iya yecarbon dioxide welding.

(3) High welding quality Nekuda kweiyo slag gasi yakasanganiswa kuchengetedzwa, inogona kunyatso dzivirira gasi rinokuvadza kubva pakupinda munzvimbo yewelding.Pamusoro pezvo, nguva yekuvepo kwedziva rakanyungudutswa refu, izvo zvinoita kuti gasi rinonaya, saka weld ine yakaderera hydrogen content uye yakanaka porosity kuramba.

(4) Kuchinja kwakasimba kunongoda kugadzirisa kuumbwa kweiyo solder wire cored, inogona kusangana nezvinodiwa zvesimbi dzakasiyana pane weld kuumbwa.

Ndezvipi zvakaipira zve flux-cored arc welding?

Izvo zvikanganiso zve flux-cored arc welding ndezvizvi zvinotevera.

Kuenzaniswa negasi shielded welding, mutengo wewelding waya wakakwira uye maitiro ekugadzira akaomarara.

② Kudyisa waya kwakaoma, zvinodikanwa kushandisa muchina wekudyisa waya une kudzvanywa kwayo kunogona kugadziriswa nemazvo.

③ Iyo cartridge iri nyore kutora unyoro, saka zvinodikanwa kuchengeta waya welding zvakasimba.

④ Slag kubviswa kunodiwa mushure mekuputira.

⑤ Hutsi huzhinji uye magasi anokuvadza anogadzirwa mukugadzirisa kwekugadzira, saka kufefetera kunofanira kusimbiswa.

Ndeipi gasi rekudzivirira rinowanzoshandiswa mu flux-cored arc welding?Ndeapi maitiro emumwe nemumwe?

Flux cored wire arc welding inowanzo shandisa pure carbon dioxide gasi kana carbon dioxide uye argon gasi segasi rinodzivirira.Mhando yegesi inoda kusarudzwa maererano ne-flux-cored wire inoshandiswa.

Argon iri nyore ionized, saka zviri nyore kuwana ejection shanduko mu argon arc.Kana iyo argon yemukati yemusanganiswa gasi isiri pasi pe75%, iyo flux cored waya arc welding inogona kuwana yakagadzikana jet shanduko.Nekudzikira kweargon yemukati, kudzika kwekupinda kunowedzera, asi kugadzikana kwearc kunoderera uye mwero we spatter unowedzera.Naizvozvo, iyo yakakwana gasi musanganiswa ndeye 75% Ar + 25% CO2.Mukuwedzera, Ar + 2% O2 inogonawo kushandiswa kusanganisa gasi.

Kana CO2 gasi yakachena yasarudzwa, inoora pasi pekuita kwekupisa kwearc uye kuburitsa huwandu hukuru hwemaatomu eokisijeni, iyo inozoita oxidize manganese, silicon uye zvimwe zvinhu mudziva rakanyungudutswa, zvichitungamira mukupiswa kwealloying element.Naizvozvo, welding waya ine yakakwira manganese uye nesilicon yemukati inofanira kushandiswa.

Nguva yekutumira: Chivabvu-09-2023