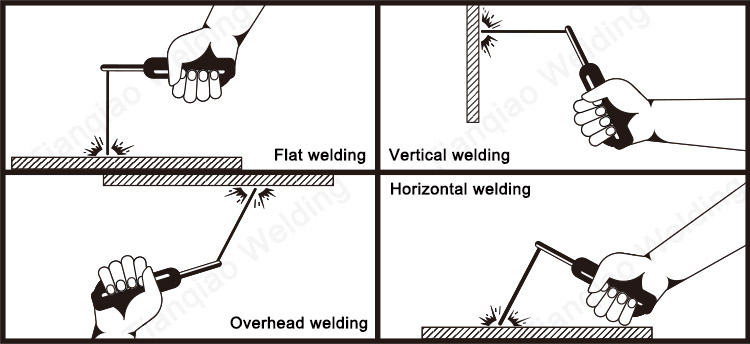

Chinzvimbo chewelding chinorehwa kana welding, hukama hwepakati penzvimbo yeweld kune welder.

Mufananidzo 1. Tianqiao welding positon

Mufananidzo 1. Tianqiao welding positon

Kune flat welding, horizontal welding, vertical welding uye overhead welding.Flat welding inoreva kuchoserwa kwakachinjika kunoitwa neanopisa akakotamisa musoro wake, saka inonziwo downhand welding;kuitira weld muT-shaped connection, iyo T-shaped weldment inowanzoiswa pa 45 ° kuti iite nzvimbo yekubatanidza yepasi yekushongedza seam, iyo inonzi ship welding.Horizontal welding (Horizontal welding) zvinoreva kuchoserwa kwakachinjika kunoitwa nemucheri pahurefu hwakafanana neruoko.Vertical welding (Vertical welding) zvinoreva kuchoserwa kuzasi-kumusoro kwakatwasuka neanopisa.Welding (overhead welding) zvinoreva musono wakachinjika unoitwa nemucheki akatarisa mudenga.Flat welding ndiyo iri nyore kuve nechokwadi chemhando yewelding, yakachinjika welding ndiyo yechipiri, vertical welding ndiyo yechitatu, uye overhead welding ndiyo yakanyanya kuoma kuve nechokwadi chemhando uye inofanirwa kudzivirirwa zvakanyanya sezvinobvira.

Mufananidzo 2. Tianqiao flat welding

Mufananidzo 2. Tianqiao flat welding

Flat welding

Welding maitiro e flat welding:

1. Simbi yeweld inonyanya kutsamira pahuremu hwayo pakuchinja kuenda kudziva rakanyungudutswa.

2. Chimiro uye simbi yedziva yakanyungudutswa zviri nyore kuchengetedza uye kutonga.

3. Pamasimbi emagetsi ane hupamhi hwakafanana, iyo welding ikozvino muflat welding chinzvimbo yakakura kupfuura iyo mune dzimwe nzvimbo dzewelding, uye kugona kwekugadzira kwakakwira.

4. Slag uye dziva rakanyungudutswa rinowanzosangana, kunyanya kana welding flat fillet welds, slag iri nyore kutungamirira uye kuumba slag kubatanidzwa.

*Hazvisi nyore kusiyanisa slag yeasidhi welding tsvimbo kubva padziva rakanyungudutswa;iwo maviri ealkaline welding tsvimbo akajeka;iyo HG20581 yakajairwa inotaura zvakajeka kuti asidhi welding tsvimbo haigone kushandiswa muClass II uye III midziyo.

5. Zvisina kufanira welding parameters uye mashandiro anogona kutungamirira nyore kune hurema hwakadai seweld bead, undercut, uye welding deformation.

6. Kana rutivi rwekumashure rwe-single-side welding rwakaumbwa zvakasununguka, weld yekutanga inotarisana nemaitiro asina kuenzana ekupinda uye kuumbwa kwemashure kusina kunaka.

Iwo welding mapoinzi e flat welding:

1. Maererano nehupamhi hweplate, yakakura dhayamita electrode uye yakakura welding ikozvino inogona kushandiswa.

2. Paunenge uchiputira, tsvimbo yekugadzira uye weldment inoita angle ye 60 ~ 80 °, uye kupatsanurwa kwe slag uye simbi yemvura inodzorwa kudzivirira kuti slag irege kuonekwa mberi.

3. Kana kukora kweplate kuri kushoma kana kuenzana ne6mm, butt flat welding inowanzova netype I groove, uye musono we welding wemberi unofanirwa kunge uri welding pfupi-arc ine φ3.2 ~ 4 electrode, uye kudzika kwekupinda kunogona. kusvika 2/3 yehupamhi hweplate;musana usati wavharwa, Hazvina kudiwa kuchenesa midzi (kunze kwezvivako zvakakosha), asi slag inofanira kucheneswa uye ikozvino inogona kuva yakakura.

4. Kana pasina kujeka kusanganiswa kweslag nesimbi yakanyungudutswa yedhamu mubutt flat welding, iyo arc inogona kurebeswa, electrode inogona kurerekera mberi, uye slag yakanyungudutswa inogona kusundirwa kumashure kwedziva rakanyungudutswa kudzivirira kuiswa kwe slag.

5. Paunenge uchiputira horizontally inclined welds, upslope welding inofanira kushandiswa kudzivirira kuiswa kwe slag uye dziva rakanyungudutswa kubva kuenderera mberi kudzivisa kuiswa kwe slag.

6. Paunenge uchishandisa multi-layer uye multi-pass welding, teerera kune nhamba yewelding passes uye welding sequence, uye imwe neimwe layer haifaniri kudarika 4 ~ 5mm.

7. Kune flat-angle welded joints of T type, corner joint, uye overlap joint, kana ukobvu hwemahwendefa maviri akasiyana, kona yetsvimbo yewelding inofanira kugadziriswa kuti ibvise arc kune rumwe rutivi rweplate gobvu, kuitira kuti mahwendefa maviri apise zvakaenzana.

8. Chisarudzo chakarurama chekutumira nzira

(1) Kana ukobvu hwewelding huri pasi kana kuenzana ne6mm, nyora I groove butt flat welding.Kana welding kaviri-sided inogamuchirwa, iyo yekumberi welding seam inotora mutsara wakatwasuka, unononoka zvishoma;iyo yekumashure welding seam inotorawo mutsara wakatwasuka, uye welding ikozvino yakakura zvishoma., Nekukurumidza.

(2) Kana kukora kweplate iri ≤6mm, pakuvhura mamwe ma grooves, multi-layer welding kana multi-layer multi-pass welding inogona kushandiswa.Yekutanga layer yepasi welding inofanira kushandisa diki ikozvino electrode, diki chiyero ikozvino, yakatwasuka mutsara kana sawtooth.Shape transport bar welding.Yekuzadza layer welding, yakakura dhayamita electrode uye pfupi arc welding ine yakakura welding ikozvino inogona kusarudzwa.

(3) Kana ukuru hwegumbo re flat fillet welding yeT-joint iri pasi pe6mm, imwe-layer welding inogona kushandiswa, uye mutsara, oblique ring kana zigzag-shaped yekutakura nzira inogona kushandiswa;kana ukuru hwegumbo hukuru, multi-layer welding kana multi-layer welding inofanira kushandiswa.Multi-pass welding, yepasi welding inotora mutsara strip yekufambisa nzira, uye iyo yekuzadza layer inogona kusarudza oblique sawtooth kana oblique denderedzwa strip yekufambisa.

(4) Kazhinji, multi-layer uye multi-pass welding inofanira kusungirirwa nenzira yakarurama-mutsara wekutakura.

Mild simbi electrodes akakodzera flat welding variAWS E6013, AWS E6010, AWS E6011, AWS E7018.

Mufananidzo 3. Tianqiao vertical welding

Mufananidzo 3. Tianqiao vertical welding

Vertical welding

Iyo welding maitiro e vertical welding:

1. Dziva resimbi rakanyungudutswa uye slag yakanyungudutswa inowira nekuda kwehuremu hwavo uye zviri nyore kuparadzanisa.

2. Kana tembiricha yedziva yakanyungudutswa yanyanya, simbi yakanyungudutswa yedhamu iri nyore kudonhedza pasi kuti iite urema hwakadai seweld bead, undercut, slag inclusion, zvichingodaro, uye weld haina kuenzana.

3. Mudzi weT-joint weld iri nyore kugadzira kupinda kusina kukwana.

4. Chiyero chekupinda chiri nyore kubata.

5. Welding kugadzirwa kwakaderera pane flat welding.

Izvo zvakakosha zve vertical welding:

1. Chengetedza kona yewelding tsvimbo;

2. Mukugadzira, vertical vertical welding inowanzoshandiswa, uye vertical vertical welding inoda matanda anokosha ekushongedza kuti ave nechokwadi chemhando ye weld.Ikozvino welding ye vertical up welding i 10 ~ 15% idiki pane iyo ye flat welding, uye diki electrode dhayamita (<φ4mm) inofanira kusarudzwa.

3. Shandisa arc welding pfupi kupfupisa chinhambwe kubva padonhwe kusvika padziva rakanyungudutswa.

4. Shandisa nzira yakarurama yekutumira.

(1) T-groove butt joint (inowanzo shandiswa kune mahwendefa matete) kana vertical welding inoitwa, linear, zigzag, crescent-shaped strip welding inowanzoshandiswa, uye kureba kwearc hakupfuuri 6mm.

(2) Pakuvhura mamwe marudzi e groove butt vertical welding, the first layer of weld inowanzobatanidzwa neyakatyoka, yakaita secrescent uye yakaita triangular-shaped strip welding ine diki diki.Gare gare, imwe neimwe layer inogona kushandiswa kune crescent kana zigzag striping.

(3) Panguva yekubatanidza yakatwasuka yemajoini akaumbwa neT, tsvimbo yekubatira inofanira kuva nenguva yakakodzera yekugara pamativi ese uye makona ekumusoro emusono wewelding, uye swing amplitude yetsvimbo yekushinha haifanire kunge yakakura kudarika hupamhi hwewelding. musono.Kushanda kwetsvimbo yewelding kwakafanana neyeimwe vertical welding ine grooves.

(4) Paunenge uchitsvaira chivharo chekuvhara, chimiro chepamusoro che weld chinotarirwa nenzira yekufambisa.Mitsara yakaita seCrescent inogona kushandiswa pakushongedza seam seam nepamusoro zvinodiwa;zigzag mitsetse inogona kushandiswa kune yakati sandara (iyo concave chimiro chepakati chakabatana nenguva yekumbomira).

Mild simbi electrodes akakodzera vertical welding variAWS E6013, AWS E6010, AWS E6011, AWS E7018, kunyanyaE6011inokodzera vertical up-bottom welding.

Mufananidzo 4. Tianqiao pamusoro welding

Overhead welding

Welding maitiro epamusoro welding:

1. Simbi yakanyungudutswa inodonha nekuda kwesimba rinokwevera zvinhu pasi, uye chimiro nekukura kwedziva rakanyungudutswa hazvifanirwe kudzorwa.

2. Zvakaoma kutakura mutsara, uye pamusoro peiyo weldment haina kukodzera kuputika.

3. Zvikanganiso zvakadai sekuiswa kwe slag, kupinda kusina kukwana, weld bead uye kuumbwa kwehurombo husina kunaka zviri nyore kuonekwa.

4. The yakanyungudutswa weld simbi splashes uye kupararira, izvo zvinogona kukonzera scalding tsaona nyore.

5. Kubudirira kwepamusoro welding yakaderera pane yezvimwe zvinzvimbo.

Welding mapoinzi epamusoro welding:

1. Welding pamusoro butt welds.Kana ukobvu hweweldment huri pasi kana kuenzana ne4mm, shandisa type I grooves uye shandisa φ3.2mm welding rods ine mwero welding current;kana ukobvu hwewelding hwakakura kupfuura kana kuenzana ne5mm, multi-layer uye multi-pass welding inofanira kushandiswa.

2. The welding seam yeT-shaped joint is overhead welding.Kana rutsoka rwekupisa rusingasviki 8mm, imwe-layer welding inofanira kushandiswa, uye kana tsoka yemotori yakakura kupfuura 8mm, multi-layer uye multi-pass welding inofanira kushandiswa.

3. Maererano nemamiriro chaiwo, tora nzira yakarurama yekutumira:

(1) Kana saizi yetsoka yewelding idiki, iyo mutsara kana mutsara inodzoreredza mhando inoshandiswa kupedzisa imwe-layer welding;kana hukuru hwetsoka yemoto yakakura, iyo yakawanda-layer welding kana multi-layer multi-pass welding inogona kushandiswa, uye yekutanga inofanira kushandiswa Straight line transport, mamwe mapeji anogona kusarudza oblique triangle kana oblique mhete yekufambisa nzira.

(2) Hazvinei kuti ndeupi rudzi rwenzira yekufambisa inotambirwa, simbi yeweld haifanirwe kunge yakawandisa pese painoenda kudziva rakanyungudutswa.

Mild simbi electrodes akakodzera pamusoro pamusoro welding variAWS E6013, AWS E6010, AWS E6011, AWS E7018

Mufananidzo 5. Tianqiao horizontal welding

Mufananidzo 5. Tianqiao horizontal welding

Horizontal welding

Welding maitiro ehorizontal welding:

1. Simbi yakanyungudutswa inowira nyore pamugero nekuda kwehuremu hwayo, ichikonzera kuremara pasi pedivi repamusoro, uye teardrop-shaped weld bead kana kusakwana kwekupinda mukati kudivi rezasi.

2. Simbi yakanyungudutswa uye slag zviri nyore kuparadzanisa, zvishoma senge vertical welding.

Key points of horizontal welding:

1. Magaro akabatana akachinjika welding grooves anogaroita V-shepeed kana K-shaped, butt joints ane plate ukobvu hwe3~4mm anogona kusonwerwa mativi ese ane type I grooves.

2. Shandisa dhayamita diki welding tsvimbo, welding ikozvino idiki pane flat welding, pfupi arc operation, inogona kudzora zviri nani kuyerera kwesimbi yakanyungudutswa.

3. Paunenge uchipinza mahwendefa akakora, kuwedzera kune yepasi weld, zvinokurudzirwa kushandisa multi-layer uye multi-pass welding.

4. Kune akawanda-layer uye akawanda-pass welding, kutarisisa kwakakosha kunofanirwa kubhadharwa pakudzora kureba kwepakati pakati pe weld pass.Kune yega yega inopindirana welding, tanga welding pa 1/3 yeyakapfuura weld kudzivirira kusaenzana.

5. Zvinoenderana nemamiriro ezvinhu chaiwo, chengetedza iyo yakakodzera welding tsvimbo angle, uye welding kasi inofanira kunge yakavharika uye yunifomu.

6. Shandisa nzira yakarurama yekutumira.

(1) Kune Type I butt yakachinjika welding, zviri nani kushandisa inodzokorodza linear strip nzira yekumberi welding seam;dzakatwasuka kana diki oblique denderedzwa mitsetse inofanira kushandiswa kune dzakakora zvikamu, uye mitsetse yakatwasuka kudivi rekuseri, uye welding ikozvino inogona kuwedzerwa zvakakodzera.

(2) Shandisa imwe bevel butt yakatwasuka welding.Kana gaka riri diki, welding yepasi inogona kushandisa mitsetse yakatwasuka;kana gwanza rakakura, chikamu chepasi chinotora mitsara inodzokororwa;apo mamwe mapeji ari akawanda-layer welding, iyo yakatenuka strip inogona kushandiswa.Yakatwasuka-mutsara yekufambisa inofanirwa kushandiswa kutakura denderedzwa yemitsara uye akawanda-layer uye akawanda-pass welding.

Mild simbi electrodes akakodzera horizontal welding variAWS E6013, AWS E6010, AWS E6011, AWS E7018

Nguva yekutumira: Jul-21-2021