Iyo inonzi hunyanzvi hwekushongedza inzira dzakareruka dzekushongedza, kururamisa kwekona ye electrode uye kushanda, uye wako welds hauzove wakanyanya kushata.

Pakutanga kwekushongedza, nekuda kwekushayikwa kwehunyanzvi hweiyo welding rhythm uye isina hunyanzvi hwekubata maitiro, zvinokonzeresa kumbomira.Kana yakadzika uye isina kudzika, inokonzeresa pores nyore, Kunyora kwakafanana, sitiroko nesitiroko.

Kukanganisa kwakawanda kwewelding:

1.External undercut

Welding process parameter kusarudzwa hakuna kunaka kana kuvhiya kwacho hakusi chiyero, welding pamwe nechepasi simbi zvikamu zvekuumbwa kwegororo kana kuora mwoyo, kunozivikanwa sekuruma kumucheto.(Pakutanga nomoto nokuti havazivi kukura ano uye nomoto ruoko kusagadzikana zviri nyore kukonzera kurumwa, kudzivirira kuruma ndiko kudzidzira nomoto unyanzvi, inofanira kugadzikana, usazvidya mwoyo.)

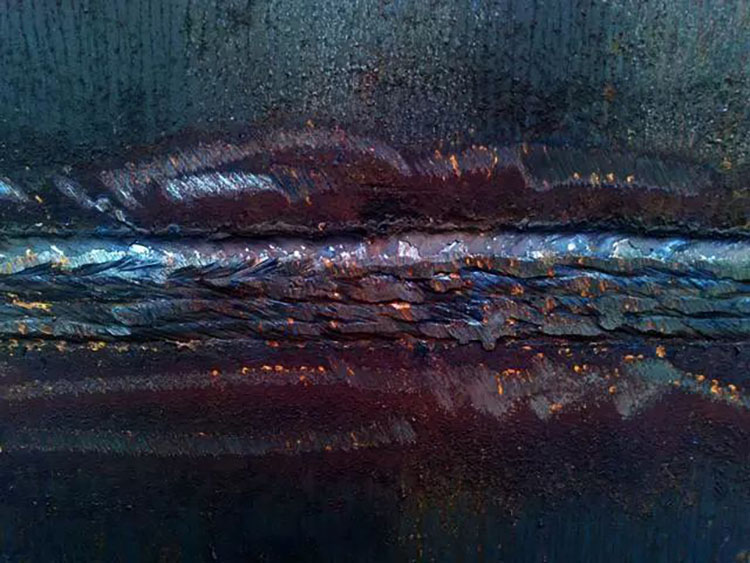

Uyu mufananidzo weiyo undercut

2.Stomata

Panguva yewelding, gasi riri mudziva rakanyungudutswa rinotadza kubuda kana raoma roramba riri mugomba roita gomba rinonzi porosity.(Pakutanga welding, nekuda kwekusakwanisa kubata welding rhythm uye kubata kusina unyanzvi kwezvipfeko, kunokonzera kumira. Kana yakadzika uye isina kudzika, ichaita nyore nyore pores. Calligraphy uye kunyora zvakafanana, imwe chete stroke panguva.)

Iri ndiro buri remhepo rewelding

3.Haina kupindwa, kwete kusanganiswa

Pane zvikonzero zvakawanda zvekupinda kusina kukwana uye kupinza, senge diki diki weld gap kana groove angle, yakanyanyisa gobvu mupendero, yakakura yakawandisa electrode dhayamita, kukurumidza welding kumhanya kana kureba arc, nezvimwe. Zvinogonekawo kuti welding mhedzisiro inogona kukanganiswa nekusachena mugomba, uye kusvibiswa kusina kunyungudika kunogona kukanganisawo fusion mhedzisiro ye weld.

(Ingodzora kumhanya kwewelding, ikozvino uye mamwe maparamendi ekuita panguva yewelding, sarudza nemazvo saizi yegroove, uye bvisa chiyero uye tsvina pamusoro pegorofu; mudzi wekuseri kwechivharo welding unofanirwa kunyatsocheneswa.)

Kupinda kusina kukwana

4.Kusvirwa

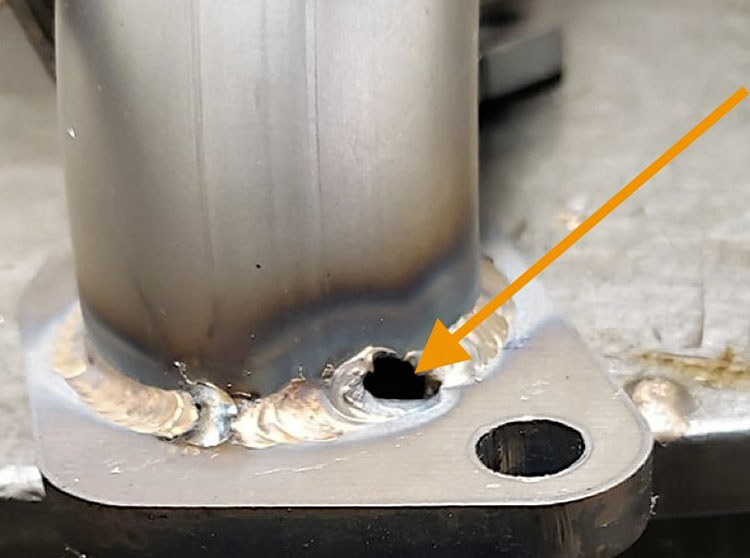

Mukati mekugadzira, simbi yakanyungudutswa inoyerera ichibva kuseri kwegorofu, ichigadzira chirema chine maburi chinonzi burn-through.(Nzira yekudzivirira ndeyekudzikisa ikozvino uye kuderedza weld gap)

Welding mifananidzo inopisa nepakati

5.Unsightly welding surface

Kukanganisa kwakadai sekupeta uye serpentine bead zvese zvinokonzereswa nekunonoka kwewelding kumhanya uye yakaderera welding ikozvino.(Nzira yekuzvidzivirira ndeyekudzidzira zvakanyanya uye kubata kukurumidza kwakakodzera kwewelding. Vanhu vazhinji vachaita izvi pakutanga, dzidzira zvakanyanya.)

Serpentine welding

lap welding

Nguva yekutumira: May-31-2023